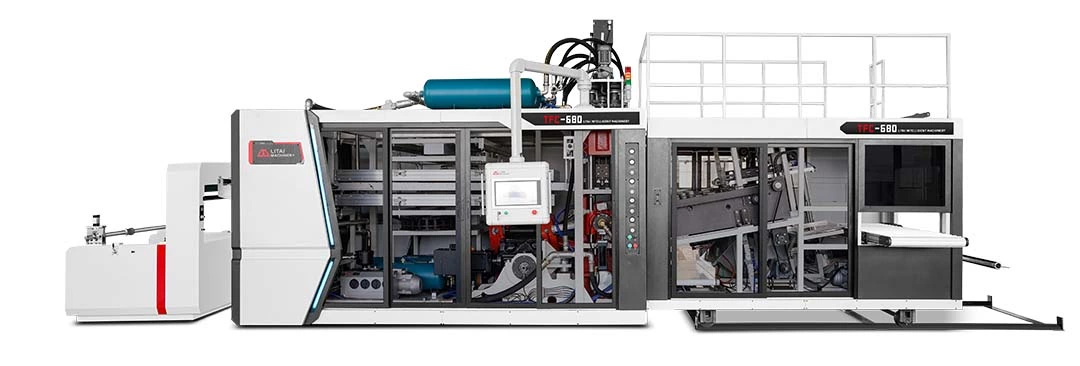

Corn Starch Cup Thermoforming Machine

1. Product Overview

The corn starch cup thermoforming machine is a production equipment with environmental protection and high efficiency as the core concept. It uses bio-based raw materials (such as corn starch, PLA, etc.) to make degradable tableware, which is particularly suitable for the molding and production of disposable cups. With the global emphasis on environmental protection, this equipment has become an ideal choice for various industries to achieve green transformation and is widely used in food packaging, catering services, industrial packaging and other fields. The equipment uses a comprehensive process of heating, vacuum forming and cooling to ensure that the finished product is high in strength, light in weight and degradable, meeting the requirements of modern green production.

2. Product Features

1. Application of environmentally friendly materials

Corn starch is used as the main raw material to reduce dependence on petrochemical-based plastics.

The finished product is 100% biodegradable and can be decomposed into water and carbon dioxide in the natural environment after being buried in the soil, without residual pollution.

2. Advanced thermoforming technology

The high-efficiency heating system is adopted to ensure that the raw materials are heated evenly and reduce material waste.

Equipped with precision vacuum forming technology, the product has a clear outline and higher strength.

3. Efficient production capacity

Support large-scale continuous production to meet high-demand scenarios.

The mold switching is fast, adaptable to a variety of specifications, and improves production flexibility.

4. Intelligent operating system

Equipped with PLC control and touch screen operation interface, production parameters are adjusted in real time, simple and easy to use.

Intelligent detection function, real-time monitoring of equipment operation status, reducing fault downtime.

5. Low energy consumption design

The equipment adopts high-efficiency energy-saving motors and heating modules to minimize energy consumption while meeting production needs.

Low production noise and friendly working environment.

- Technical parameters

| MAIN TECHNICAL PARAMETER | |

| Machine Model | TFC-680 |

| Forming Area(L x W mm) | 680×320 |

| Forming Depth(Max.) | 170mm (180mm requires typesetting) |

| Sheet Width | 510-730mm |

| Suitable Sheet thickness | 0.3-2.0mm |

| Machine Forming Speed(Max.) | ≤42 times/min(depends on different products) |

| Air Pressure | 0.8-1.0Mpa |

| Air Consumption | 4000~5000 L/min |

| Water Consumption | 260 L/min |

| Water Pressure | ≥0.5Mpa (Can't turn on without enough pressure) |

| Suitable Sheet Materials | PP/PS/PET/PVC/PLA/Degradable material/etc |

| Power Supply | 380V 50HZ 3PHASE 4WIRE |

| Rated Power | 174KW |

| Heating rating | 129.6KW+ 2KW(preheating) |

| Punching Force | 32T |

| Procedure | Heating--Forming/Cutting--Stacking |

| Machine dimensions | L 10700mm* W 3088mm* H 3215mm |

| Machine Weight | 13.5T |

4. Core components and functions

1. High-precision mold system

Adopt aviation-grade alloy materials, wear-resistant and long service life.

The mold surface is precisely processed to ensure the product size is accurate and the surface is smooth and flawless.

2. Vacuum forming and cooling system

The high-performance vacuum pump provides stable negative pressure to improve the molding quality.

The high-speed cooling device accelerates the molding efficiency and ensures the strength and toughness of the product.

3. Automatic feeding and waste recycling system

The automatic feeding device improves the utilization rate of raw materials and saves labor costs.

Waste can be recycled and reprocessed in a centralized manner to achieve zero waste production.

4. Intelligent temperature control module

The precise temperature control system avoids overheating or underheating and ensures the best performance of raw material performance.

5. Application scenarios

1. Food industry

Take-out catering: disposable beverage cups, soup cups.

Packaged food: ice cream cups, yogurt cups, juice cups, etc.

2. Hotel and event scenarios

The demand for environmentally friendly tableware in star-rated hotels, cafes, weddings and other occasions.

3. Industrial and commercial use

Advertising cups, brand customization, increase product added value.

6. Advantage Analysis

1. Compliance with environmental protection policies

The products have passed a number of international environmental certifications (such as FDA, CE certification) and meet the environmental protection regulations of different regions.

It can help enterprises enhance their green brand image and enhance their market competitiveness.

2. Cost-effectiveness optimization

Automated production reduces labor demand and significantly reduces operating costs.

High production efficiency shortens order delivery time and improves customer satisfaction.

3. Diversified development potential

Supports the development of a variety of products, such as meal bowls, etc., to open up more market space for enterprises.

Mold customization is flexible, and we can work with customers to create personalized product solutions.

7. After-sales service guarantee

We provide customers with the following after-sales support:

1. Equipment installation and commissioning: Professional team door-to-door service to ensure that the equipment quickly enters the production state.

2. Technical training: Free operation and maintenance training to improve the skills of operators.

3. Warranty service: The equipment enjoys a 12-month warranty and responds to customer needs quickly.

4. Upgrade and expansion support: Provide mold modification and equipment function upgrade services to meet the long-term development needs of enterprises.

Conclusion

The corn starch cup thermoforming machine is an advanced equipment that combines environmental protection concept with efficient production. It not only meets the pursuit of green and sustainable development in modern society, but also provides enterprises with high-quality production solutions. By adopting this equipment, enterprises can enhance their market competitiveness and contribute to global environmental protection.

Welcome to inquire for more details! We look forward to working with you to move towards a green future together!