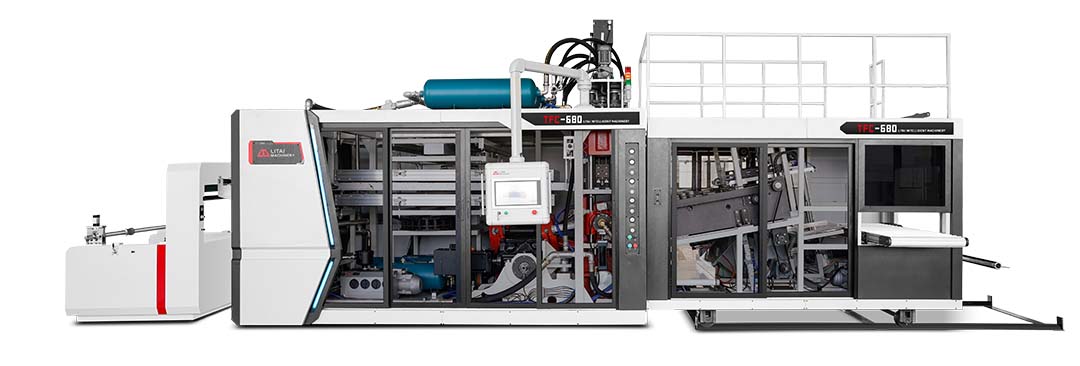

Disposable Plastic Cups Manufacturing Machine

Product Overview

The disposable plastic cups manufacturing machine is a professional equipment that integrates efficiency, flexibility and intelligent control, and is designed to provide customized solutions for various food and beverage companies. The equipment can efficiently produce disposable plastic cups of different specifications and materials to meet various market needs, such as fast food, takeaway, cold drinks and hot drinks. With its modular design and high degree of automation, the machine has a significant differentiated competitive advantage in the field of plastic cup manufacturing.

Product highlights

Modular design, flexible production

The equipment adopts a modular structure, and different functional modules can be selected according to the actual needs of users, such as quick mold replacement module, automatic stacking packaging module, etc. This flexible design allows users to easily adjust the production configuration in the production line and quickly respond to market changes and customized needs.

Intelligent control system

Equipped with an advanced PLC control system, users can monitor the production status in real time through the touch screen and remotely control the equipment. The system not only supports full automation, but also can be intelligently adjusted according to material and production requirements to optimize energy consumption and production efficiency. A variety of preset programs help reduce the complexity of manual operation and improve the convenience of operation.

Refined production, reduced waste

The machine adopts a high-precision molding process to ensure that the thickness, weight and shape of each cup are consistent. Combined with an intelligent detection system, unqualified products are automatically removed, material waste is reduced, and the accuracy and yield of production are improved. This has significant cost control advantages for companies that produce large quantities of disposable plastic cups.

Green material compatibility

In addition to traditional PP and PET materials, the machine also supports the production of plastic cups made of degradable and environmentally friendly materials (such as PLA) to meet the current market demand for environmentally friendly packaging. This provides more choices for enterprises and conforms to the trend of global sustainable development.

Low noise, high efficiency

The equipment adopts advanced silent technology. Even in high-intensity production, the noise during operation is controlled at a low level, improving the factory environment. This provides a comfortable working environment for workshop workers. At the same time, the equipment can operate around the clock to ensure maximum production efficiency.

Personalized customization service

According to the brand needs of different customers, the equipment supports printing and color customization, and directly prints customer brands and patterns on the cup body during the production process, reducing post-processing links and reducing production costs. Brand owners can use this function to quickly launch personalized products that meet market trends.

Technical Parameters

| MAIN TECHNICAL PARAMETER | |

| Machine Model | TFC-680 |

| Forming Area(L x W mm) | 680×320 |

| Forming Depth(Max.) | 170mm (180mm requires typesetting) |

| Sheet Width | 510-730mm |

| Suitable Sheet thickness | 0.3-2.0mm |

| Machine Forming Speed(Max.) | ≤42 times/min(depends on different products) |

| Air Pressure | 0.8-1.0Mpa |

| Air Consumption | 4000~5000 L/min |

| Water Consumption | 260 L/min |

| Water Pressure | ≥0.5Mpa (Can't turn on without enough pressure) |

| Suitable Sheet Materials | PP/PS/PET/PVC/PLA/Degradable material/etc |

| Power Supply | 380V 50HZ 3PHASE 4WIRE |

| Rated Power | 174KW |

| Heating rating | 129.6KW+ 2KW(preheating) |

| Punching Force | 32T |

| Procedure | Heating--Forming/Cutting--Stacking |

| Machine dimensions | L 10700mm* W 3088mm* H 3215mm |

| Machine Weight | 13.5T |

Application scenarios

Disposable plastic cups manufacturing machines are not limited to the field of beverage packaging, but can also be used for packaging and production of foods such as ice cream, salads, fruit cups, yogurt, etc. It is particularly suitable for large chain catering companies, takeaway service providers, and fast food restaurants in shopping malls that require diversified packaging solutions.

After-sales and support

We provide users with a full range of after-sales services, including online remote support, on-site technical guidance, and regular equipment maintenance recommendations. Free maintenance is provided during the warranty period to ensure stable operation of the equipment, and regular upgrades and optimization recommendations are provided to customers to help improve long-term production benefits.

Conclusion

With modular design, intelligent control and green environmental compatibility, the disposable plastic cups manufacturing machine not only meets the high efficiency requirements of the modern market, but also takes into account environmental trends and personalized needs. It is an ideal choice for the fast food, beverage and food packaging industries to increase production capacity and innovation. This equipment not only improves production flexibility, but also provides strong support for customers' brand building and market competition.