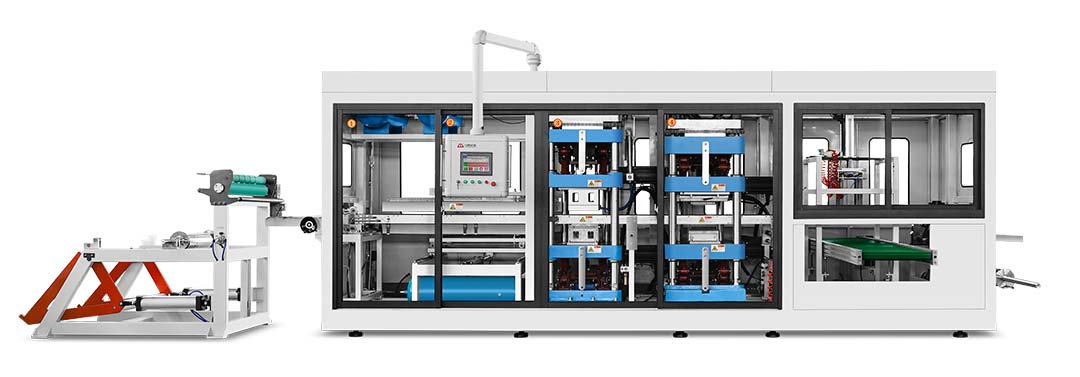

Egg tray thermoforming machine

Egg tray thermoforming machine is a kind of equipment specially used for producing egg trays, which is usually used in food packaging industry, especially for packaging of poultry eggs. The equipment processes raw materials such as various plastic sheets into egg trays of various specifications and shapes through thermoforming technology.

Product Overview

The egg tray thermoforming machine is an efficient and automated production equipment that uses thermoforming technology to heat, mold, and cool plastic sheets into egg trays. It is widely used in supermarkets, farms, and egg manufacturers to provide safe and stable packaging for various eggs, avoid egg damage during transportation, and improve storage and transportation efficiency.

Main features

Automated production: The equipment adopts a fully automatic control system, which automatically completes the process from feeding, heating, molding to discharging, is easy to operate and saves labor costs.

Efficient and energy-saving: Through the precise temperature control system and efficient energy utilization design, energy consumption is reduced, the molding cycle is shortened, and production efficiency is greatly improved.

Replaceable mold: The egg tray thermoforming machine is equipped with molds of various specifications, which can produce egg trays of different specifications, shapes and capacities according to demand to meet the needs of different markets.

Applicable environmentally friendly materials: Recyclable plastics and other materials can be used to meet environmental protection requirements and respond to the trend of sustainable development.

Compact structure: The equipment has a reasonable design, compact layout, and small footprint, which is suitable for the production needs of small and medium-sized enterprises.

Stable product quality: The molded egg tray has excellent strength and toughness, which ensures the durability and pressure resistance of the product and can effectively protect egg products.

Technical Parameters

| MAIN TECHNICAL PARAMETER | |

| Model | TTF-520A |

| Forming Area | 520mm x 400 mm |

| Forming Depth (Max.) | 110mm |

| Sheet thickness | 0.2-1.6mm |

| Forming Speed (Max.) | 30times/min |

| Air pressure | 0.6-0.8mpa |

| Air consumption | 3.0 m³/min |

| Water consumption | 0.7 m³/h |

| Sheet width (Max.) | 550mm |

| Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA etc. |

| Power supply | AC 380V, 50Hz, Three-phase, Four-wire |

| Used power | 50Kw |

| Rated power | 120Kw |

| Heating power | 75Kw |

| Procedure | Forming-cutting-stacking |

| Dimension | L8200*W4650*H2670mm |

| Weight | About 9.0T |

Scope of application

Egg tray thermoforming machines are widely used in the packaging of eggs, duck eggs, goose eggs and other poultry and egg products. In addition to the production of egg trays, other types of food trays or industrial product trays can also be produced by changing molds, which has strong scalability.

Advantages

High cost performance: The equipment is durable and has low maintenance costs, which can significantly reduce production costs and improve economic benefits.

Production flexibility: Egg trays and trays of different specifications can be customized according to customer needs to adapt to different market needs.

Easy to operate: The user-friendly operating system allows even novices to get started quickly, reducing training costs.

With its high efficiency, energy saving and environmental protection, the egg tray thermoforming machine has become an important equipment in egg packaging production, helping enterprises to gain an advantage in the fierce market competition.