Four-station plastic thermoforming machine TTF-520AF

Product Overview

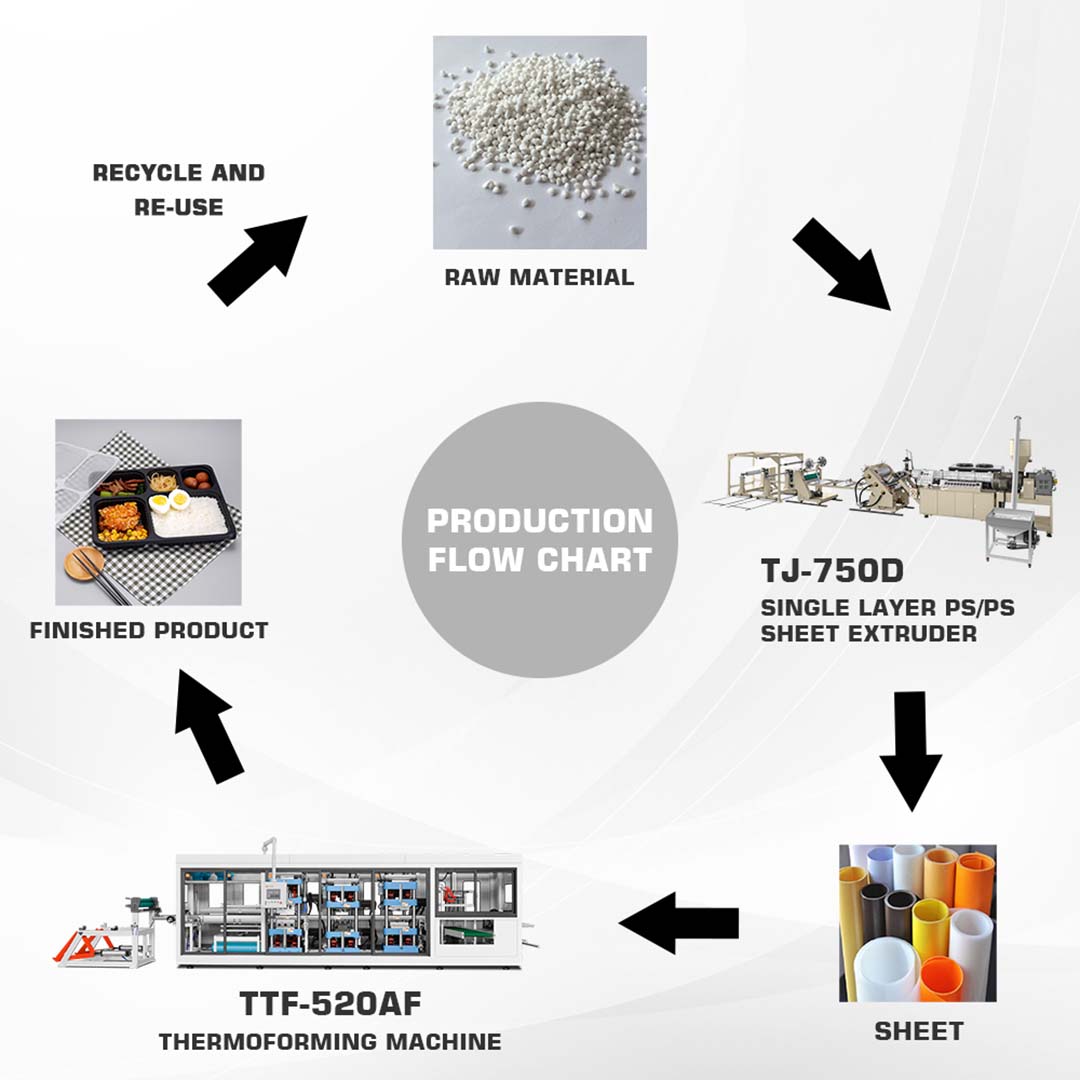

TTF-520AF four-station plastic thermoforming machine is an advanced equipment designed for efficient and large-scale production of plastic products. Through a series of operations such as heating, forming, punching, cutting, and stacking of plastic sheets, plastic products of various shapes and specifications can be quickly produced. It is widely used in food packaging, medical equipment, electronic product housings, and daily necessities, and is an important equipment in the modern plastic processing industry.

Main Features

Four-station efficient design

Operation process

Loading station: Double-station coil supply device, the maximum coil diameter is 900mm. The system will automatically transport the sheet to the heating station.

Heating station: The efficient heating system uses infrared heating technology to evenly heat the plastic sheet, ensuring that the material is evenly heated to reach the optimal molding temperature.

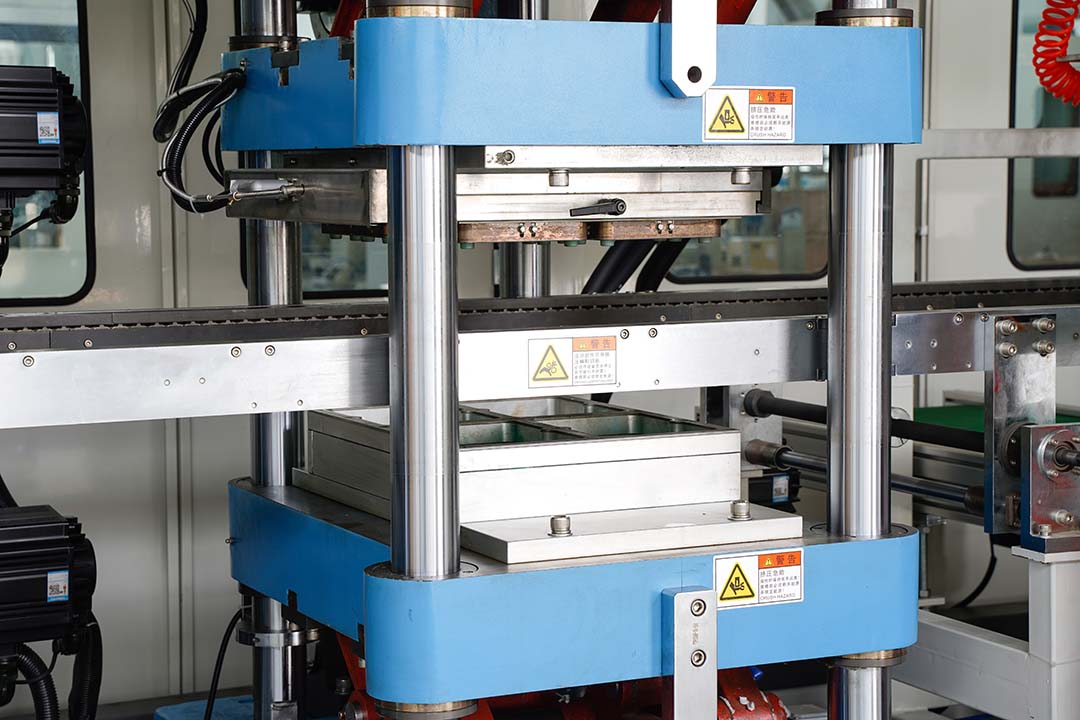

Molding station: Advanced mold design and pressing technology enable the plastic sheet to be precisely formed in the molding mold, ensuring the consistency and high quality of each product.

Punching station: The press drives the punch to press down quickly, and punches holes in the plastic product through the punching die.

Cutting station: The automatic cutting system cuts the formed products into individual finished products according to the preset program, with neat cutting edges and no secondary processing required.

High-precision control system

The touch screen human-machine interface is convenient and fast. It can store 100 sets of mold data and corresponding parameters, which are convenient to call when used.

Accurately control key parameters such as temperature, time, and pressure to ensure the stability of the production process and product quality.

Real-time data monitoring and feedback make it convenient for operators to adjust production parameters in time.

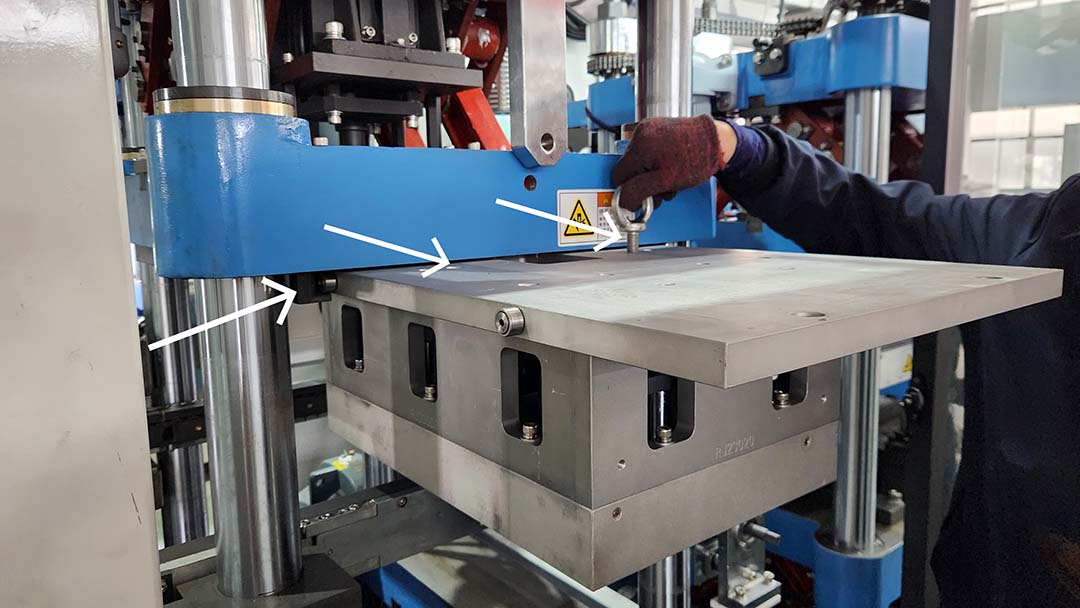

Flexible mold replacement

Electrically adjust the distance between workstations, which is fast and convenient. Molds of different specifications and shapes can be quickly replaced according to production needs.

The mold is made of high-strength material, which is wear-resistant and durable, ensuring accuracy and stability in long-term use.

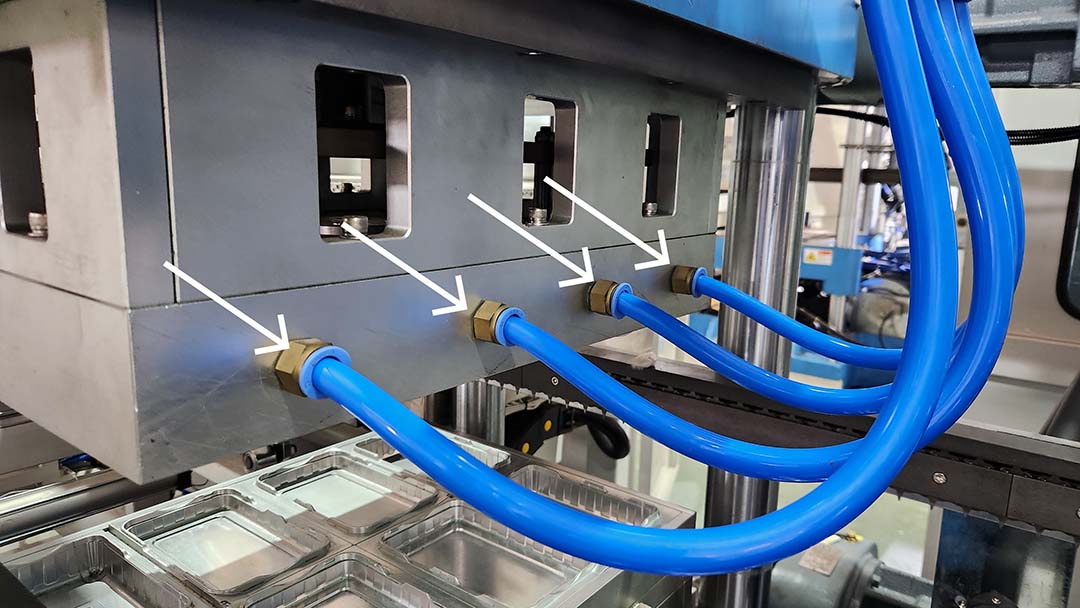

Efficient cooling system

Built-in rapid cooling device ensures that the plastic products are quickly cooled and shaped after molding, reducing deformation and shrinkage.

The cooling system uses circulating water cooling, which is highly efficient and energy-saving.

Energy-saving and environmentally friendly design

The sheet waste generated by the plastic thermoforming machine during the production process can be recycled. By recycling the waste, the pollution of plastic waste to the environment is reduced, and the environmental burden caused by landfill and incineration of plastic waste is reduced.

Reprocessing and reusing waste can save a lot of virgin plastic materials and save oil resources.

Using recycled materials can reduce production costs and improve the economic benefits of enterprises.

Promoting enterprises to move towards green and sustainable development is in line with the requirements of modern society for environmental protection and sustainable use of resources.

Technical parameters

| MAIN TECHNICAL PARAMETER | |

| Model | TTF-520AF |

| Forming Area | 520mm x 400 mm |

| Forming Depth (Max.) | 110mm |

| Sheet thickness | 0.2-1.6mm |

| Forming Speed (Max.) | 30times/min |

| Air pressure | 0.6-0.8mpa |

| Air consumption | 3.0 m³/min |

| Water consumption | 0.7 m³/h |

| Sheet width (Max.) | 550mm |

| Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA etc. |

| Power supply | AC 380V, 50Hz, Three-phase, Four-wire |

| Used power | 55Kw |

| Rated power | 136Kw |

| Heating power | 75Kw |

| Procedure | Forming-punching-cutting-stacking |

| Dimension | L10800*W4650*H2670mm |

| Weight | About 11.0T |

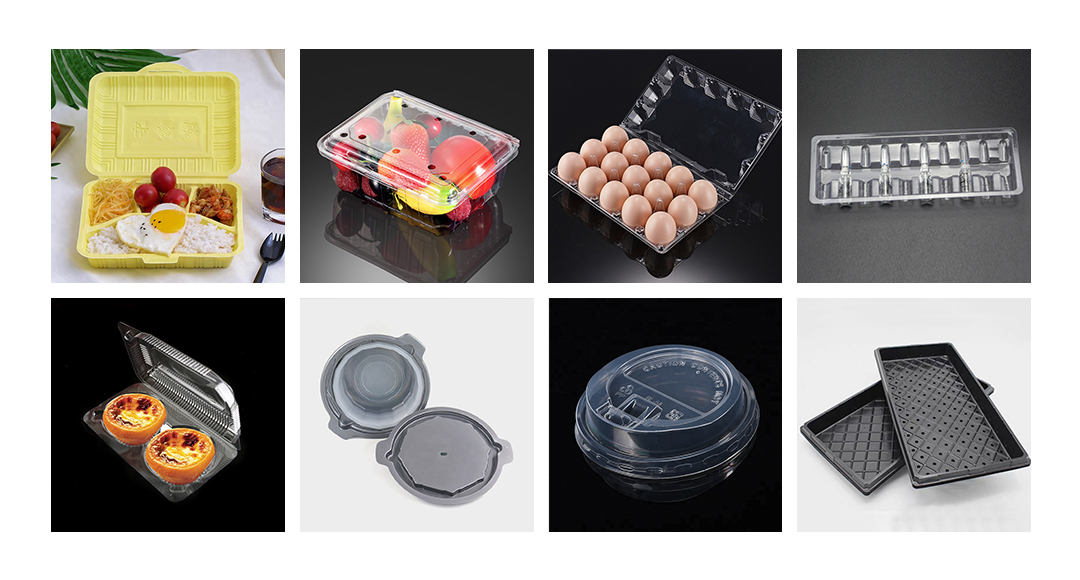

Application Areas

Food packaging

Various plastic trays, bowls, boxes, etc., suitable for fast food restaurants, supermarkets, catering companies, etc.

Medical equipment

Disposable medical supplies, such as medical trays, syringe shells, drug packaging boxes, etc., meet the high hygiene standards of the medical industry.

Electronic products

Plastic shells of electronic products, such as mobile phone shells, earphone boxes, remote control shells, etc., ensure the protection and beauty of the products.

Daily necessities

Various daily necessities, such as plates, toothbrush holders, storage boxes, etc., meet the daily needs of families and offices.

After-sales service

We provide customers with comprehensive after-sales services, including:

Equipment installation and commissioning: Professional technicians provide door-to-door service to ensure the normal operation of the equipment.

Operation training: Provide customers with detailed equipment operation training so that operators can quickly master the use methods.

Regular maintenance: Regularly inspect and maintain equipment to extend the service life of equipment and ensure stable production.

Technical support: Provide technical support and troubleshooting services at any time to ensure uninterrupted production for customers.

Conclusion

TTF-520AF four-station plastic thermoforming machine has become an important equipment in the plastic products industry with its high efficiency, precision and flexibility. We are committed to providing customers with high-quality products and services to help customers improve production efficiency and achieve greater business value. If you have any questions or needs about our products, please feel free to contact us. We look forward to working with you to jointly promote the development of the plastic products industry.