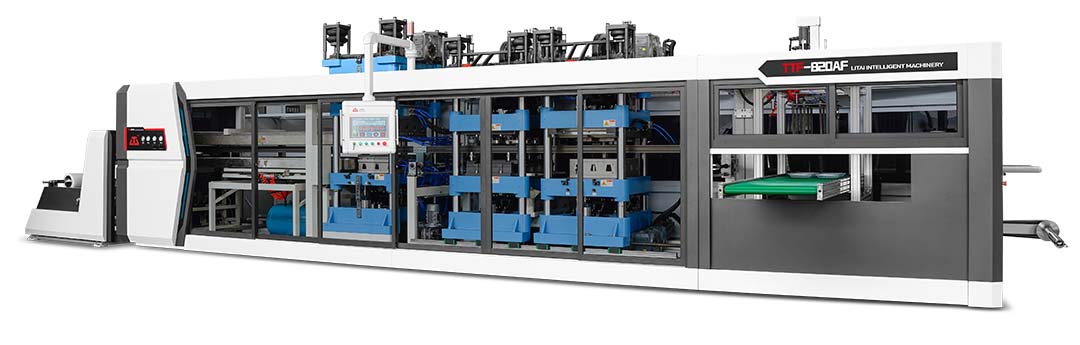

Fruit box cover thermoforming machine

The fruit box cover thermoforming machine is a plastic forming machine specially designed for fruit box covers, integrating advanced thermoforming technology, efficient production speed and flexible mold design. It can not only meet the needs of mass production of precision plastic covers, but also provide exclusive packaging solutions for different fruit types, sizes and packaging styles. As the market's requirements for food packaging quality, environmental protection and efficiency continue to increase, the fruit box cover thermoforming machine has become the preferred equipment for packaging companies pursuing quality and cost-effectiveness.

1. Product design highlights

Modular mold design: The equipment adopts a modular mold system, which allows the specifications of the lid to be quickly replaced and adjusted. This design not only improves production flexibility, but also effectively reduces switching time and adapts to today's diverse packaging needs. The depth, diameter, and texture of the fruit box lid can be precisely controlled to provide suitable protection and display effects for different fruits such as strawberries, grapes, and blueberries.

Precise temperature control system: The core heating device is equipped with multi-point temperature control technology, which can monitor and fine-tune the mold temperature in real time to ensure that the plastic is evenly heated and not easily deformed. The temperature control accuracy can reach ±1℃, avoiding cracking, warping and other problems caused by uneven temperature, so that each lid has good sealing and aesthetics.

Intelligent molding monitoring: The equipment has a built-in advanced PLC control system and is equipped with a high-definition touch screen panel to display the working status of each production stage in real time. The operator can intuitively monitor parameters such as temperature, molding pressure, cooling time, and automatically alarm when encountering abnormal conditions, improving operational safety and efficiency.

2. Efficient and energy-saving production advantages

High-speed production: The fruit box lid thermoforming machine has a high production speed and is suitable for mass production and peak order needs. Its efficient molding method combined with automatic stacking and packaging functions can save users a lot of labor and time costs.

Low energy consumption design: The equipment effectively reduces energy consumption through the heat recovery system and reduces unnecessary energy loss. At the same time, the optimized motor design further reduces power consumption, reducing carbon footprint while ensuring production efficiency, and is more environmentally friendly.

Environmentally friendly material support: Unlike traditional equipment, the fruit box cover thermoforming machine can adapt to the molding needs of biodegradable materials such as PLA (polylactic acid) and recyclable PET materials, which is in line with the environmental protection trend of modern packaging and brings green production advantages to enterprises.

3. Detailed explanation of product functions

Automatic feeding and waste recycling: The equipment is equipped with an automatic feeding system, which automates the entire process from raw material delivery to molding operations, reducing manual intervention. In addition, the waste recycling function is integrated to ensure that the scraps are directly recycled and reused to reduce resource waste.

Adjustable molding pressure: Through fine control of the pressure, it is ensured that the lid has sufficient sealing after molding to avoid accidental air leakage during transportation. In addition, the intelligent adjustment of molding pressure can also meet the production needs of lids of different thicknesses and different flexibility, further expanding the scope of application.

Cooling and separation of finished products: The molded lid is quickly cooled to maintain the toughness and stability of the plastic, and the finished product is automatically separated from the mold through a separator. This process is smooth and avoids deformation or scratching of the lid, which improves the product yield.

- Technical parameters

| MAIN TECHNICAL PARAMETER | |

| Machine Model | TTF-820AF |

| Forming Area(L x W mm) | 820 x 650mm |

| Forming Depth(Max.) | 140mm |

| Suitable Sheet Width | 480~850mm |

| Transmission accuracy of sheet pull track (mm) | 0.5mm |

| Forming clamping height | 420~570mm |

| Punching clamping height | 279-379mm |

| Cutting clamping height | 259~359mm |

| Max.Stacking height | 300mm |

| Upper mold stroke | 170mm |

| Lower mold stroke | 170mm |

| Suitable Sheet thickness | 0.2~2mm |

| Machine Forming Speed(Max.) | 30times/min |

| Air Pressure | 0.6~0.8Mpa |

| Air Consumption | 4.2m³/min |

| Water Consumption | 1m³/hour |

| Suitable Sheet Materials | PP/PS/PET/PVC/HIPS/PLA/CORN STARCH/etc |

| Power Supply | 380V 50HZ 3PHASE 4WIRE |

| Current | 490A |

| Clamping force(KN) | 650KN |

| Cutting length(m) | 17m |

| Station servo motor | 7.5KW |

| Rated Power | 246KW |

| Heating Power | 171KW |

| Procedure | Forming-Punching-Cutting-Stacking |

| Machine dimensions | 13000X4300mmX2800mm |

| Machine Weight | 21T |

5. Application scenarios and user value

This equipment is suitable for use in the food packaging industry, including various types of fruit planting and processing companies, as well as fruit and vegetable packaging plants in supermarkets, especially for large-scale fruit planting companies and fresh food distribution centers. The fruit box cover thermoforming machine can not only meet the company's mass production needs, but also enhance the market competitiveness of fruit products through high-quality packaging. The sealed fruit boxes are more beautiful during transportation and display, extend the shelf life, and enhance customers' trust in the products.

Summary

The fruit box cover thermoforming machine has brought great production convenience to modern food packaging companies with its excellent precision, speed and adaptability. This equipment not only improves production efficiency and product quality, but also meets the current market requirements for green packaging with its environmentally friendly design concept. It is an ideal choice for enhancing corporate competitiveness.