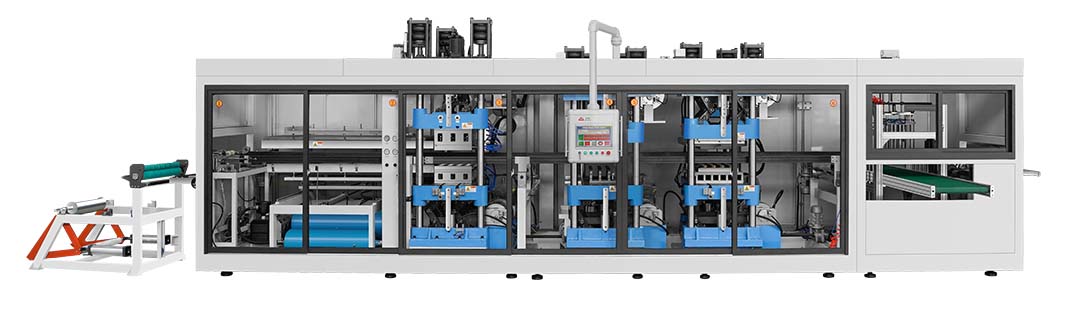

Fully automatic four-station plastic thermoforming machine TTF-700AF

Fully automatic four-station plastic thermoforming machine TTF-700AF

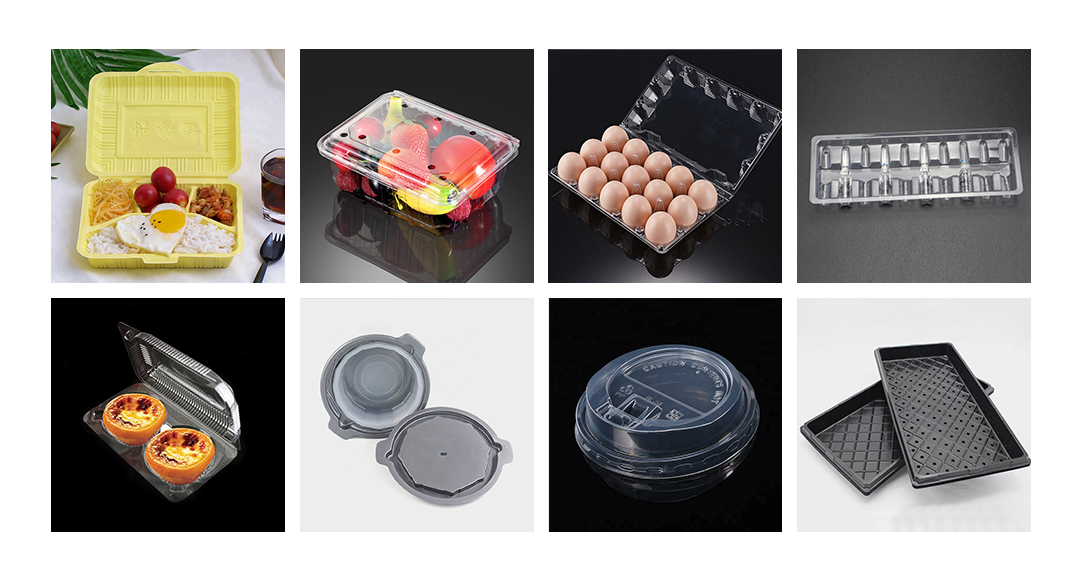

The TTF four-station series fully automatic thermoforming machine is the latest core product developed by our company. The plastic thermoforming machine integrates feeding, heating, forming, punching, cutting, stacking and waste recycling. Used in the production of disposable plastic products. Suitable for most customers' requirements, perforated plastic containers such as plastic trays, clamshell containers, lunch boxes, side hole fruit boxes, lids, nursery trays, strawberry and blueberry boxes can be produced. The machine is driven entirely by servo motors. It has stable operation, low noise, high efficiency and good quality, and can meet the production needs of plastic products of different specifications and shapes. Here is a detailed introduction to the device:

1.There is a safety door alarm function. Once the door is opened, the machine will stop or alarm, the door is closed and the machine starts to work.

2. The equipment has low center of gravity, high yield, stable operation, easy operation and beautiful appearance.

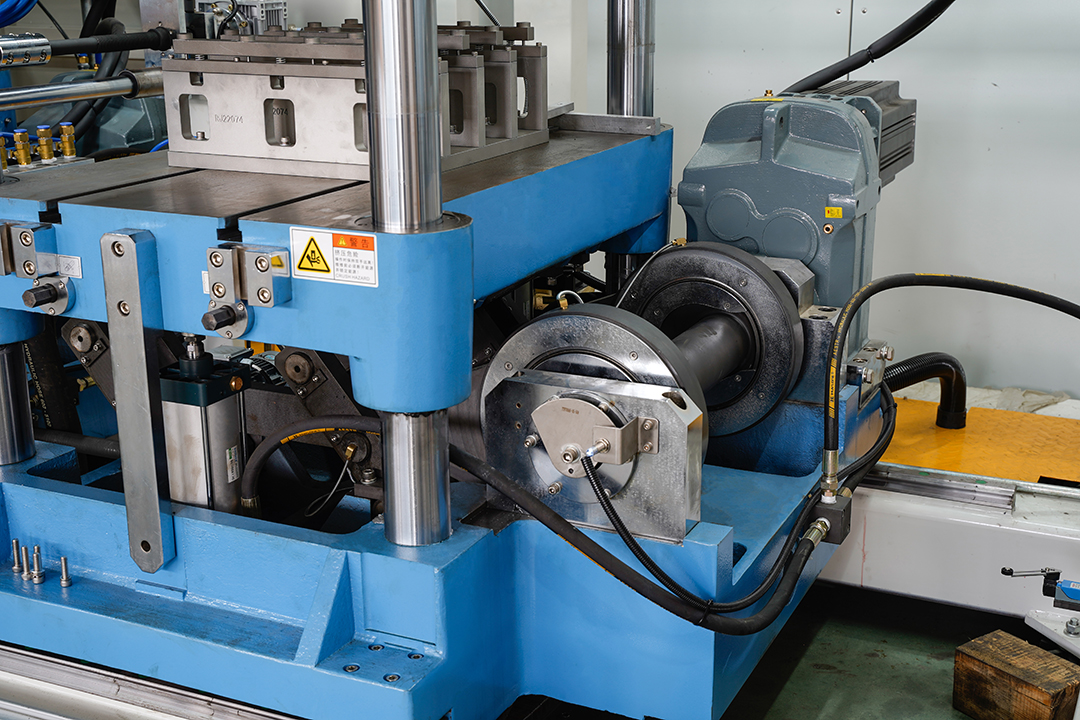

3.Adopt full servo motor drive to ensure product perfection and long life of the machine. Each servo motor is equipped with overload protection to prevent the machine from overloading.

4.The molding and punching stations are equipped with quick mold changing devices, which greatly shortens the mold changing time and reduces production costs.

5.Using Elstein's fast-response and effective temperature control module, heating tile plus vacuum insulation cotton, far red

The external heating method improves heat conversion efficiency, ensures that the plate is heated evenly, increases production speed, and saves energy.

6.The conveying part uses aluminum rails and #65Mn toothed chains, which have high hardness, good resilience, and heat resistance. There is cooling water inside to improve the plate cooling efficiency; the paper feeding is driven by a servo motor, making the paper feeding more accurate and efficient.

7.The feeding and heating parts are equipped with photoelectric switches to prevent safety accidents caused by misoperation during the production process. The loading rack is combined with the machine to save workshop space and is easy to control.

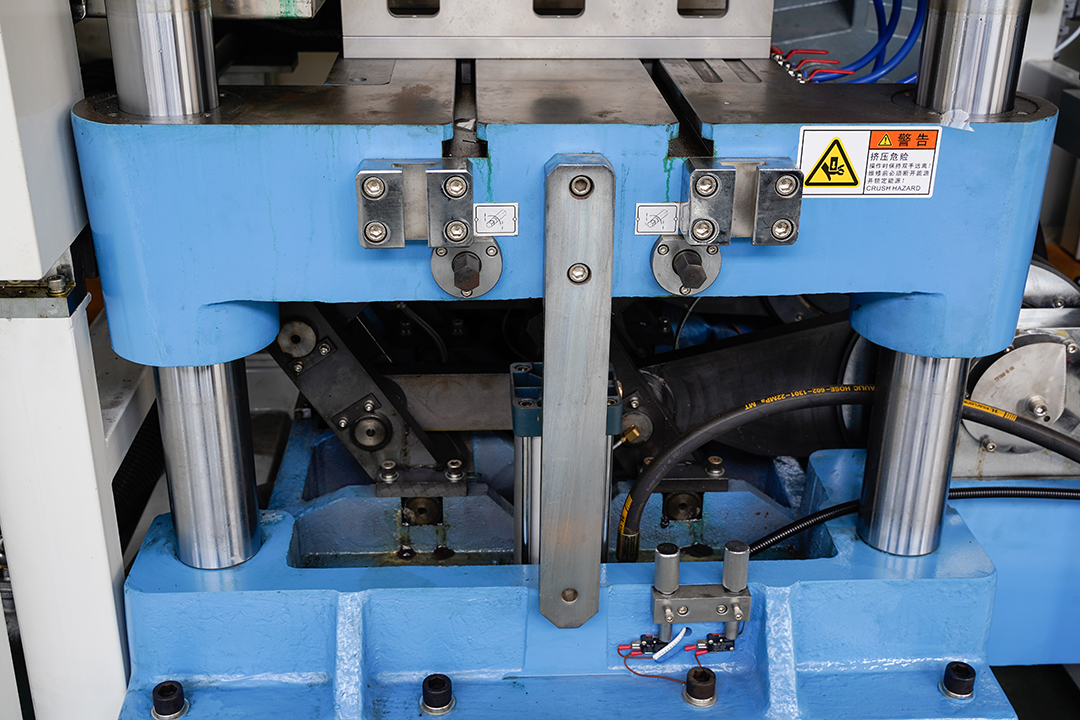

8.Each station adopts eccentric crank connecting rod structure transmission, which has higher transmission efficiency and stable and efficient operation of the equipment.

9.The intelligent console interface (Delta) has storage function. All parameters can be saved in the device to facilitate next operation.

10.Each workstation has a stable structure of four guide columns (GCr15 steel, externally hard chrome plated). Wear-resistant, extending equipment service life.

Technical Parameters

| MAIN TECHNICAL PARAMETER | |

| Model | TTF-700AF |

| Forming Area | 700mm x 550 mm |

| Forming Depth (Max.) | 120 mm |

| Sheet thickness | 0.2-1.6 mm |

| Forming Speed (Max.) | 30times/min |

| Air pressure | 0.6-0.8mpa |

| Air consumption | 3.6 m³/min |

| Water consumption | 0.7 m³/h |

| Sheet width (Max.) | 730mm |

| Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA etc. |

| Power supply | AC 380V, 50Hz, Three-phase, Four-wire |

| Used power | 105Kw |

| Rated power | 211Kw |

| Heating power | 118Kw |

| Procedure | Forming-punching-cutting-stacking |

| Dimension | L13000*W4500*H2800mm |

| Weight | About 25.0T |

1. Efficient production:

The fully automatic four-station plastic thermoforming machine TTF-700AF adopts a fully automated operating system, which can realize automated production of all processes from feeding, preheating, molding to cooling. It has a fast production cycle and a high degree of production efficiency, which greatly improves production capacity, reduces labor costs, and makes the production process more economical and efficient.

2. Precise molding:

The equipment is equipped with advanced temperature control system and pressure control system, which can accurately control heating temperature and molding pressure to ensure stable and reliable molding quality of plastic products. Through precise control, plastic products with beautiful appearance and precise dimensions can be produced to meet the various needs of customers.

3. Strong stability:

The fully automatic four-station plastic thermoforming machine TTF-700AF adopts a high-strength body structure and a stable operation system. It has good earthquake and compression resistance and can maintain stability and reliability under long-term high-intensity operation. It has undergone strict quality inspection and testing, and has a long service life and reliable performance guarantee.

4. Flexible and diverse:

TTF-700AF has strong adaptability and flexibility, and can be customized according to the different needs of customers. It can produce plastic products of various specifications and shapes, such as pallets, containers, boxes, etc. At the same time, the automated production line can be expanded and upgraded according to production needs to improve production efficiency and flexibility.

5. energy saving:

The fully automatic four-station plastic thermoforming machine adopts advanced energy-saving technology and environmentally friendly materials, has low energy consumption and emissions, and meets environmental protection requirements. During the production process, it can minimize energy consumption and waste emissions, reduce the impact on the environment, and meet the requirements of sustainable development.

Conclusion:

As an important equipment in the field of plastic product production, the fully automatic four-station plastic thermoforming machine has the advantages of efficient production, precise molding, strong stability, flexibility and diversity, environmental protection and energy saving, etc. It can meet the various production needs of customers and provide a good solution for the production of plastic products. Enterprises bring greater economic and social benefits.