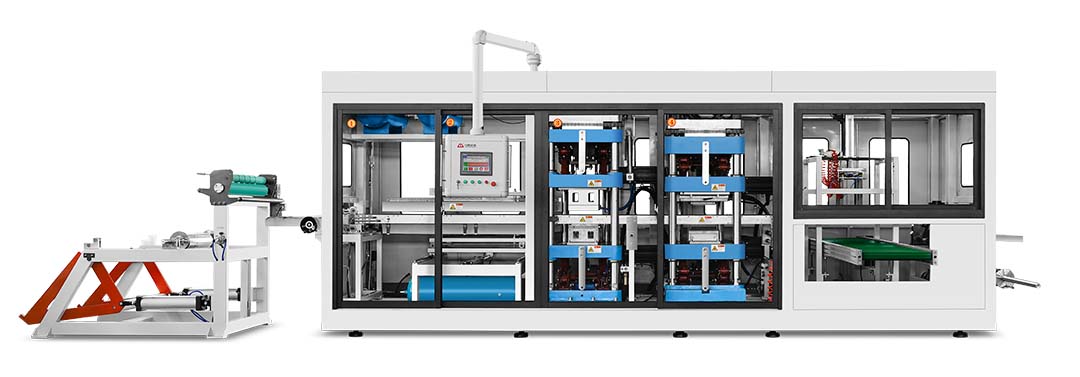

Fully automatic three-station plastic thermoforming machine 520A product introduction

Overview

The fully automatic three-station plastic thermoforming machine 520A is a molding equipment integrating high efficiency, precision and intelligence, specially designed for the plastic packaging industry. This equipment is designed to operate at the same time with three stations and is driven by a full servo motor. It has stable operation, low noise, and high efficiency, which greatly improves production efficiency. It is widely used in fields such as food, medicine, electronic products, and daily consumer goods packaging. Its automated control system makes operation easier and product quality more stable, making it an ideal choice in modern plastic molding processes.

Main features

Efficient production

Three-station design: The equipment is equipped with three workstations: forming, cutting, and stacking. The three stations work simultaneously, which greatly shortens the forming time of each product and realizes high-speed continuous production.

High-speed forming: Under the premise of ensuring product quality, the production speed can reach 15-30 times per minute (the specific speed depends on the material and product), which significantly improves production efficiency.

Precise control

PLC control system: With advanced PLC control system, users can accurately set and monitor various process parameters in real time through the touch screen interface, including temperature, pressure, molding time, etc.

Precise temperature control: The high-precision temperature control system ensures that the heating temperature of each station is uniform and stable, avoiding product quality problems caused by temperature fluctuations.

Intelligent operation

Automatic feeding: Equipped with an automatic feeding device, it can accurately feed materials according to the set program, reducing manual operation.

Automatic molding: Fully automatic molding process, from heating to cooling molding, is completed in one go, ensuring the stability of the molding process.

Automatic cutting: After forming, the product automatically enters the cutting station for precise cutting to ensure consistent product size.

Automatic stacking: The cut products are automatically stacked neatly for easy subsequent packaging and transportation.

Energy saving and environmental protection

Energy-saving heating system: adopts high-efficiency energy-saving heating technology to reduce energy consumption and improve heating efficiency.

Optimize energy management: By optimizing energy management, further reduce energy consumption, reduce production costs, and reduce the impact on the environment.

Safe and reliable

Multiple safety protections: Equipped with emergency stop button, overload protection, fault alarm and other multiple safety protection devices to ensure the safe operation of the equipment.

Solid structure design: The equipment adopts a solid mechanical structure design, which runs smoothly and reliably and reduces maintenance requirements.

Technical Parameters

| MAIN TECHNICAL PARAMETER | |

| Model | TTF-520A |

| Forming Area | 520mm x 400 mm |

| Forming Depth (Max.) | 110mm |

| Sheet thickness | 0.2-1.6mm |

| Forming Speed (Max.) | 30times/min |

| Air pressure | 0.6-0.8mpa |

| Air consumption | 3.0 m³/min |

| Water consumption | 0.7 m³/h |

| Sheet width (Max.) | 550mm |

| Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA etc. |

| Power supply | AC 380V, 50Hz, Three-phase, Four-wire |

| Used power | 50Kw |

| Rated power | 120Kw |

| Heating power | 75Kw |

| Procedure | Forming-cutting-stacking |

| Dimension | L8200*W4650*H2670mm |

| Weight | About 9.0T |

Application areas

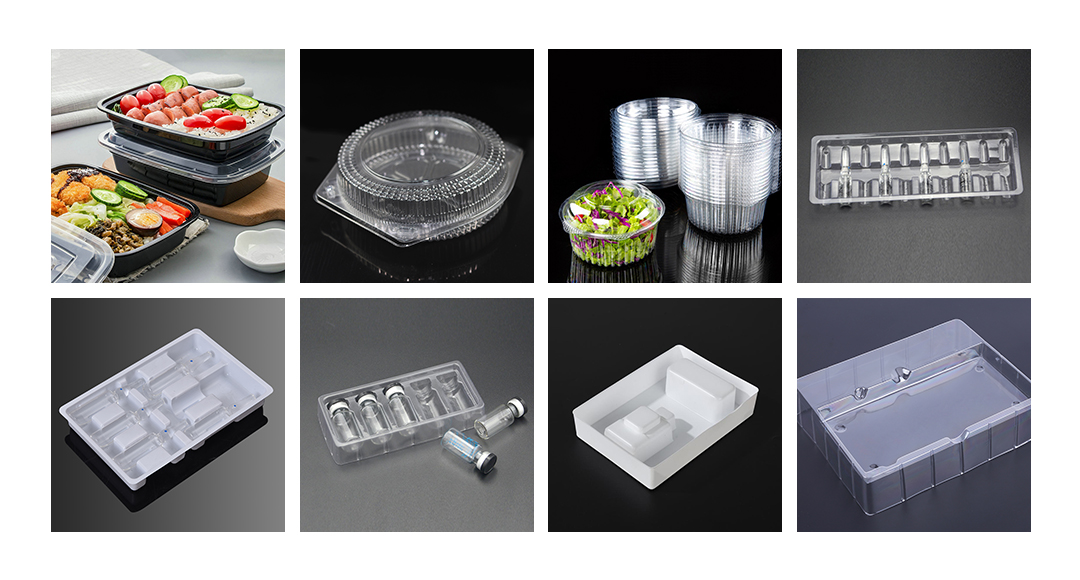

Food packaging

Manufacture food trays, jelly boxes, lunch boxes and other food packaging products.

Ensure the safety and hygiene of food packaging and meet the high standards of food packaging.

Medical packaging

Manufacture pharmaceutical packaging products such as medicine trays and test kits.

Provide packaging solutions that meet the strict requirements of the pharmaceutical industry.

Electronic product packaging

Manufacture electronic component packaging boxes, etc.

Provide high-precision and high-quality electronic product packaging.

Daily consumer goods

Manufacture plastic products for daily use such as plastic cups, bowls, and plates.

Meet the high quality and diversified needs of daily consumer goods.

Advantages

High efficiency and low cost

Through the multi-station linkage design, the production efficiency is greatly improved and the production cost of each product is reduced.

Achieve mass production to meet high output requirements.

Quality assurance

The precise temperature control and pressure control system ensures the consistent molding quality of each product.

Through a stable production process, reduce the scrap rate and improve the product qualification rate.

Easy to operate

The intelligent human-machine interface design is simple and easy to learn, which reduces the technical requirements of the operator.

The high degree of automation reduces manual intervention and improves the automation level of production.

Easy maintenance

The modular design makes the maintenance and maintenance of the equipment more convenient and quick.

The maintenance cost is low, the equipment runs stably, reduces downtime, and improves production efficiency.

Conclusion

The fully automatic three-station plastic thermoforming machine 520A has become an important equipment in the modern plastic molding industry with its high efficiency, precision and intelligence. It can not only meet the molding needs of various complex shaped products, but also greatly improve production efficiency and product quality. As an ideal choice for various plastic packaging and product manufacturers, the equipment provides customers with efficient and reliable production solutions, helping enterprises stand out in the fierce market competition.