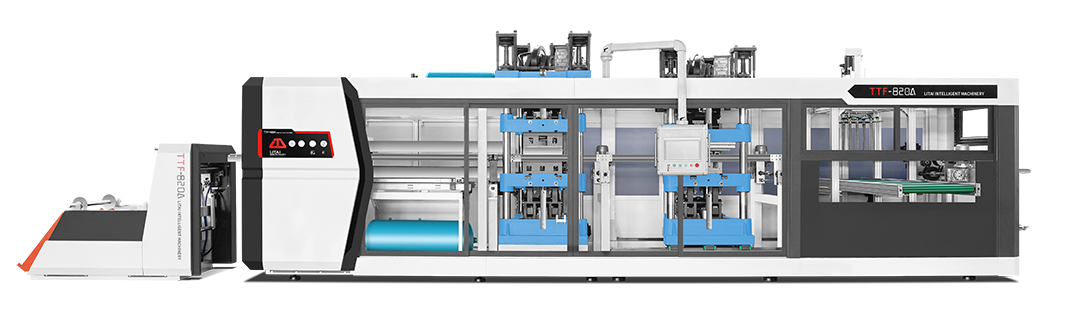

Fully automatic three-station plastic thermoforming machine TTF-820 A Introduction

The TTF series of fully automatic thermoforming machines is the core product that Litai Machinery is currently committed to developing and promoting. It integrates forming, cutting and stacking processes into one machine. It is an efficient, precise and reliable plastic molding equipment, widely used in the plastic product production industry. It adopts advanced technology and technology and can complete plastic thermoforming processing in a short time to meet the production needs of various products.

Machine overview

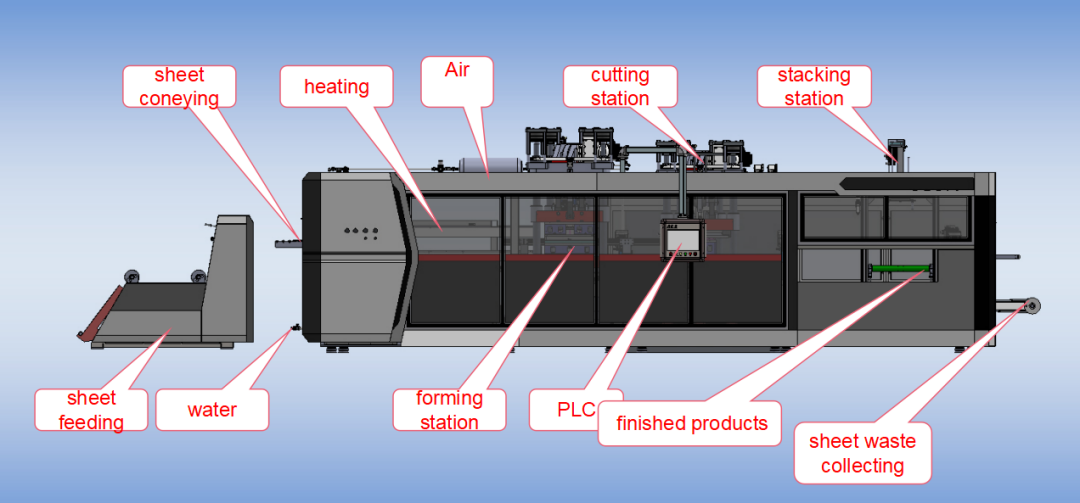

1. Square steel structure - good material and more stable;

2. Automatic loading, saving human resources, only one worker can operate, efficient and convenient;

3. Automatic paper feeding to reduce the load on the conveying servo motor;

4. Double sheet roll station, the maximum length of sheet roll diameter can reach 900mm.

The photoelectric switch can control the opening and closing of the paper feeding motor to control the paper feeding speed.

Technical features

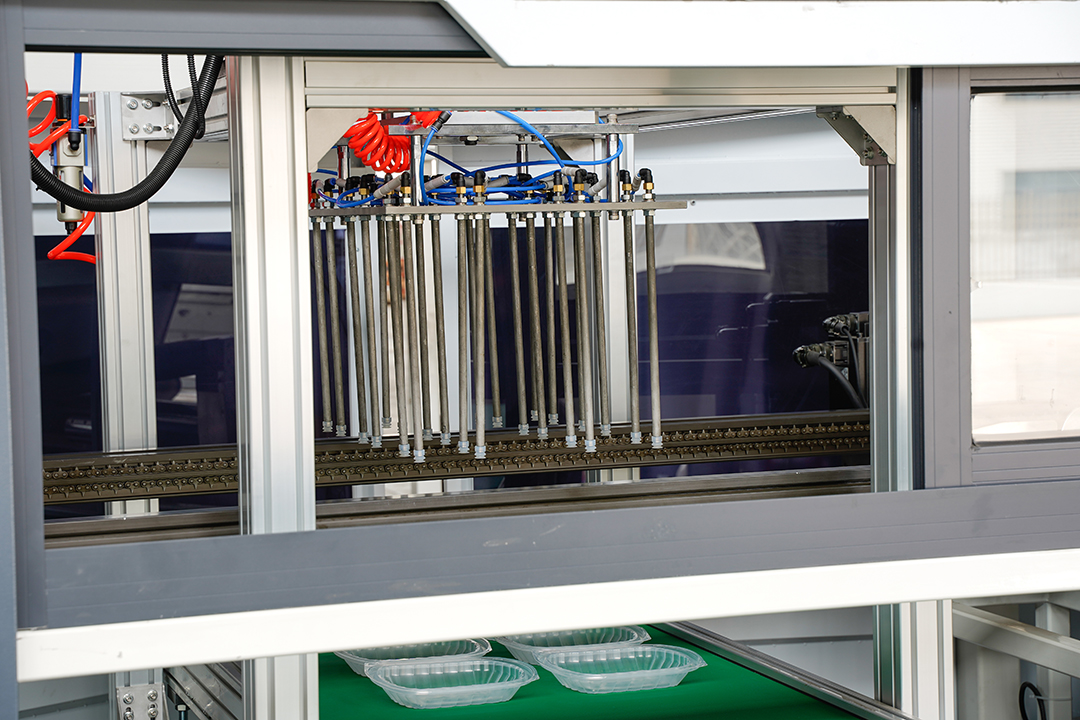

Fully automated operation: The equipment realizes fully automated operations, including feeding, heating, forming, cooling, discharging, etc., reducing manual intervention and improving production efficiency.

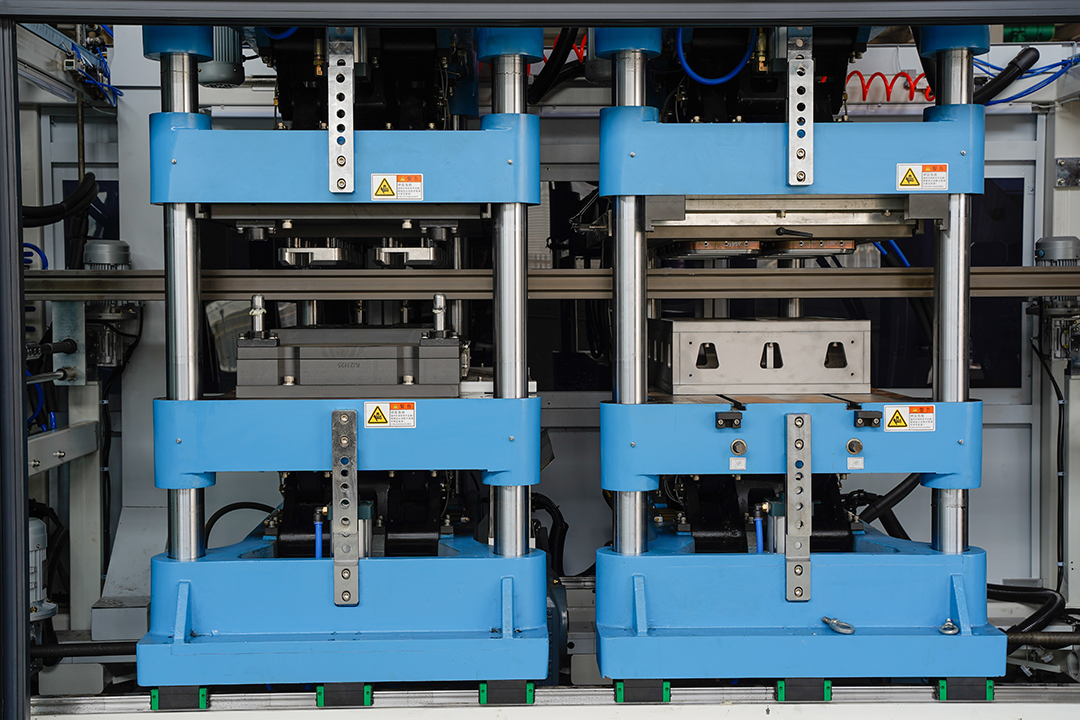

Three-station design: With three stations, multiple products can be produced at the same time, which greatly shortens the production cycle and increases production capacity.

Precision heating system: Using advanced heating technology, it can accurately control the heating temperature and time to ensure that the plastic material reaches the best molding state during processing.

Quick mold change: The equipment is equipped with a quick mold change system, which makes product change more convenient and faster, adapting to the rapid changes in market demand.

Stability and reliability: Full servo motor and various safety devices, the equipment has a stable structure and is made of high-quality materials. It has good durability and stability and can continue to operate stably for a long time.

Intelligent control system: Equipped with an intelligent control system, the operation is simple and convenient, and can achieve precise adjustment of various parameters, improving the flexibility and controllability of production.

The above, but not limited to, achieve high precision, high efficiency, energy saving, ultra-stable, easy operation, low noise, etc.

Machine details & technical parameters

| Technical Parameters | |

| MODEL | TTF820A |

| Forming Area | 820*650mm |

| Forming Depth(Max.) | 140mm |

| Forming Speed(Max.) | 30times/min |

| Sheet Thickness | 0.2-1.6mm |

| Sheet Width(Max.) | 850mm |

| Suitable Sheet | PP/PS/PVC/PET/PLA/HIPS/Corn Starch With PP etc. |

| Air Pressure | 0.6-0.8MPa |

| Air Consumption | 4.0m³/min |

| Water Consumption | 0.7m³/h |

| Heating Power | 140kw |

| Rated Power(Total) | 199Kw |

| Power Supply | AC 380V, 50Hz, Three-phase, Four-wire |

| Dimension(L*W*H) | 11800*4300*2800mm |

| Weight | About 16.5T |

|

|

Application areas

The fully automatic three-station plastic thermoforming machine TTF-820 A is widely used in the production of various plastic products, including but not limited to:

Plastic packaging containers: such as cups, boxes, trays, etc.;

Plastic tableware: such as dinner plates, tableware sets, etc.;

Plastic industrial parts: such as various shells, casings, etc.;

Plastic toys and gift products, etc.

Summarize

The fully automatic three-station plastic thermoforming machine TTF-820 A is one of the key equipment in the production of plastic products. Its high efficiency, accuracy and reliability make it an important part of the modern production line. With the continuous advancement of science and technology and the changing market demand, it is believed that the fully automatic three-station plastic thermoforming machine will play a more important role in the future and contribute to the development of the plastic product production industry.