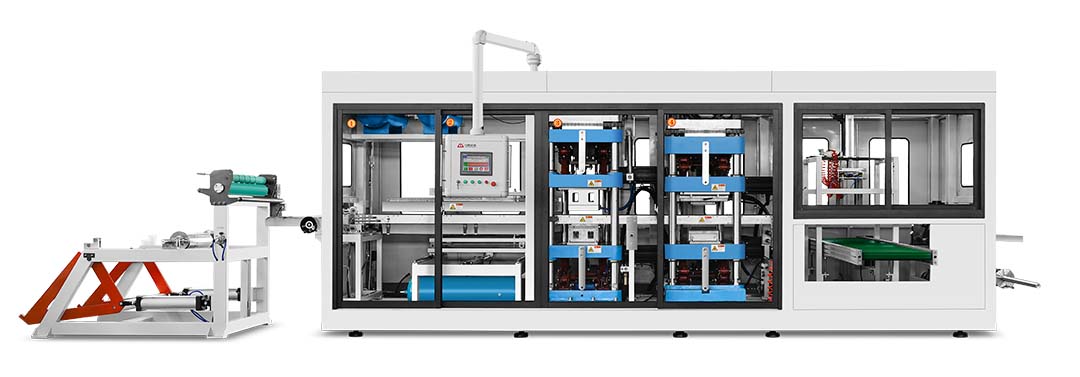

Packaging box thermoforming machine

1. Product Overview

Thermoforming machine for packaging boxes is a professional equipment used to heat and soften various thermoplastic plastic sheets (such as PVC, PET, PP, PS, etc.) and form them through vacuum or pressure molds. It produces packaging boxes, trays and other products of various specifications and shapes by uniformly heating the plastic materials and then precisely forming them. They are widely used in food packaging, medical consumables packaging, electronic product packaging, toy packaging and other fields. Thermoforming machine for packaging boxes has the advantages of high production efficiency, high molding accuracy and easy operation. It is one of the indispensable and important equipment in the modern packaging industry.

2. Product Features

1. Highly automated production process

The packaging box thermoforming machine adopts advanced automation technology and intelligent control system to realize a fully automated production process from sheet heating, forming, cutting, stacking to product output. The whole process is precisely controlled by PLC (programmable logic controller). The operator only needs to set the production parameters to achieve batch production, which greatly reduces manual intervention and improves production efficiency and product consistency.

2. Precise temperature control and energy-saving design

The equipment is equipped with an advanced temperature control system, which can accurately control the temperature of sheet heating, ensure that the plastic sheet softens within the appropriate temperature range, avoid overheating or underheating, and ensure stable molding effect. At the same time, the energy-saving design of the equipment minimizes energy consumption and greatly reduces electricity costs while ensuring efficient production.

3. Multi-material compatibility

The packaging box thermoforming machine supports the processing of a variety of thermoplastics, including PVC (polyvinyl chloride), PET (polyethylene terephthalate), PP (polypropylene), PS (polystyrene) and other materials. These materials have their own characteristics and can meet the packaging needs of different products. The equipment supports the processing of materials of different thicknesses and hardnesses, and is widely used in the production of various packaging products.

4. High-precision mold forming

The equipment adopts a high-precision mold system to ensure that each packaging box has accurate dimensions and a smooth surface. The mold design is flexible and can be customized according to customer needs to meet the production needs of packaging boxes of various specifications and shapes. The mold replacement is simple and fast, and can quickly adapt to the production switching of different product lines.

5. Intelligent operation interface

The operation interface of the equipment adopts a human-machine interaction system (HMI), which has a simple and intuitive touch screen operation function, allowing users to easily set production parameters and monitor the production process in real time. Operators can flexibly adjust parameters such as heating temperature, molding time, cutting position, etc. according to production needs to ensure that the equipment operates in the best condition.

6. Flexibility and scalability

The packaging box thermoforming machine has strong scalability and flexibility, and can adapt to different packaging needs. By changing the mold, the equipment can quickly switch to produce packaging boxes of different sizes and shapes. In addition, the equipment can also integrate other automated equipment, such as automatic stacking machines, automatic labeling machines, etc., to achieve a more efficient integrated production line layout.

3. Scope of application

1. Food packaging industry

Thermoforming machine can produce various food packaging boxes, such as disposable lunch boxes, fruit and vegetable trays, cake boxes, fast food boxes, etc. It can not only meet the requirements of food safety and hygiene, but also customize packaging boxes of various shapes and sizes to enhance the beauty and convenience of food packaging.

2. Medical packaging industry

The equipment is suitable for the production of packaging boxes for medical consumables, such as syringe trays, medical glove boxes, disposable medical device packaging boxes, etc. Through precise molding technology, the hygienic and pollution-free characteristics of medical packaging are ensured.

3. Electronic product packaging industry

It is used for protective packaging of electronic products, such as plastic packaging boxes for electronic devices such as mobile phones, tablets, and headphones. Through customized molds, the protective effect and beautiful display of the packaging boxes on the products are ensured.

4. Daily necessities and toy packaging industry

The equipment is also suitable for the production of packaging boxes for daily necessities, toys and other consumer goods, providing a variety of product display forms and enhancing the packaging attractiveness of the goods.

4. Technical Parameters

| MAIN TECHNICAL PARAMETER | |

| Model | TTF-520A |

| Forming Area | 520mm x 400 mm |

| Forming Depth (Max.) | 110mm |

| Sheet thickness | 0.2-1.6mm |

| Forming Speed (Max.) | 30times/min |

| Air pressure | 0.6-0.8mpa |

| Air consumption | 3.0 m³/min |

| Water consumption | 0.7 m³/h |

| Sheet width (Max.) | 550mm |

| Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA etc. |

| Power supply | AC 380V, 50Hz, Three-phase, Four-wire |

| Used power | 50Kw |

| Rated power | 120Kw |

| Heating power | 75Kw |

| Procedure | Forming-cutting-stacking |

| Dimension | L8200*W4650*H2670mm |

| Weight | About 9.0T |

5. Product advantages

1. Efficient and stable

The packaging box thermoforming machine adopts advanced automation design to ensure long-term stable operation of the equipment, greatly improve production efficiency, and is suitable for large-scale industrial production.

2. Environmental protection and energy saving

Through precise temperature control and energy-saving design, the equipment effectively reduces energy consumption, reduces corporate production costs, and reduces the generation of plastic waste, complying with modern environmental protection standards.

3. Quick switching and customization

Mold replacement is easy and supports rapid switching to produce packaging boxes of different specifications and shapes, greatly improving production flexibility. The equipment also supports customized mold design to meet customers' individual needs.

4. Reduce labor costs

The fully automated production line significantly reduces the need for manual operations, improves the degree of automation and product consistency of production, and reduces labor costs.

6. Summary

As an important piece of equipment in the modern packaging industry, the packaging box thermoforming machine is suitable for the packaging production needs of various industries with its superior performance of efficient automation, flexible customization, energy saving and environmental protection. It not only improves the production efficiency of enterprises, but also provides more innovation space for packaging design, helping enterprises to meet the market demand for high-quality packaging products.