PLA cup making machine

PLA cup making machine is an efficient and environmentally friendly automated equipment specially used to produce environmentally friendly cups made of polylactic acid (PLA) material. PLA, as a degradable bioplastic, is widely praised as an environmentally friendly material because it comes from plants (such as corn, sugar cane, etc.), and has gradually become an ideal choice to replace traditional petroleum-based plastics. PLA cup making machine combines modern automation technology with precision technology to provide an efficient, green and reliable production solution, which is widely used in food and beverage packaging, disposable products and environmentally friendly product manufacturing.

Main features:

1. Efficient production:

Adopting advanced automation technology, the PLA cup making machine can achieve high-speed continuous production, greatly improving production efficiency and meeting the needs of large-scale production.

2. Precision control:

Through the PLC control system and precise sensor equipment, the key parameters such as temperature, pressure and speed in the production process are accurately controlled to ensure the quality stability of the product.

3. Environmentally friendly material support:

The equipment is specially designed for PLA materials and has good adaptability. It can efficiently process PLA cups of various specifications and shapes, and maximize the environmental advantages of PLA materials.

4. Energy-saving design:

Adopting energy-saving motors and optimized heating systems, the PLA cup making machine reduces energy consumption while ensuring production speed and stability, which helps to save production costs.

5. Intelligent operation:

Equipped with a touch screen operation interface, the operation is simple and intuitive, and remote monitoring and fault diagnosis can be performed through software, reducing human operation errors and improving production safety.

6. High-precision mold:

The high-precision mold technology is used to ensure that the size and shape of each cup are consistent, reducing the scrap rate while improving the product's aesthetics and market competitiveness.

7. Versatility:

The PLA cup making machine supports customized production and can adjust the cup size, printing pattern and other personalized designs according to customer needs to meet the needs of different markets.

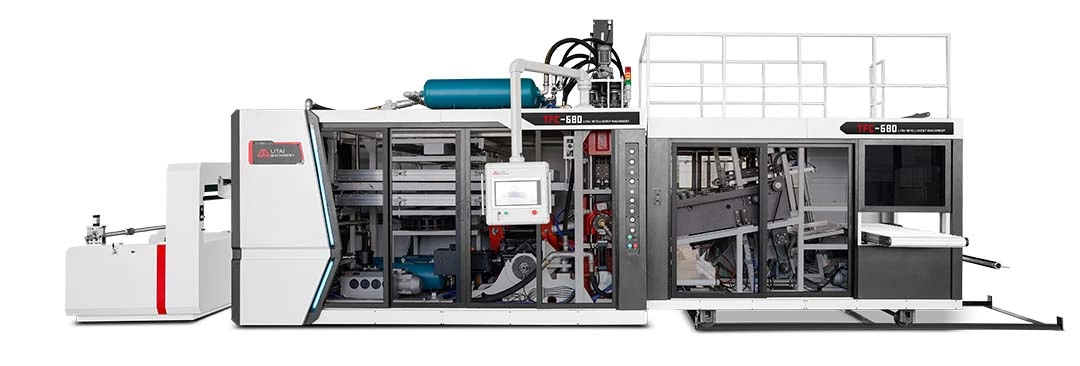

Technical parameters:

| MAIN TECHNICAL PARAMETER | |

| Machine Model | TFC-680 |

| Forming Area(L x W mm) | 680×320 |

| Forming Depth(Max.) | 170mm (180mm requires typesetting) |

| Sheet Width | 510-730mm |

| Suitable Sheet thickness | 0.3-2.0mm |

| Machine Forming Speed(Max.) | ≤42 times/min(depends on different products) |

| Air Pressure | 0.8-1.0Mpa |

| Air Consumption | 4000~5000 L/min |

| Water Consumption | 260 L/min |

| Water Pressure | ≥0.5Mpa (Can't turn on without enough pressure) |

| Suitable Sheet Materials | PP/PS/PET/PVC/PLA/Degradable material/etc |

| Power Supply | 380V 50HZ 3PHASE 4WIRE |

| Rated Power | 174KW |

| Heating rating | 129.6KW+ 2KW(preheating) |

| Punching Force | 32T |

| Procedure | Heating--Forming/Cutting--Stacking |

| Machine dimensions | L 10700mm* W 3088mm* H 3215mm |

| Machine Weight | 13.5T |

Application areas:

Food and beverage industry: production of environmentally friendly cups for the catering industry, suitable for various packaging needs such as take-out, cold drinks, hot drinks, etc.

Environmentally friendly products: production of various environmentally friendly disposable products, such as cold drink cups, hot drink cups, tableware, etc.

Advertising and promotion: the cup body pattern can be customized as an effective carrier for corporate promotion and brand publicity.

Household items: PLA cups can also be used to produce daily household items, such as small storage cups, pet food bowls, etc.

After-sales service:

The company provides customers with comprehensive after-sales service, including equipment installation and commissioning, technical training, regular maintenance, troubleshooting, etc., to ensure that the equipment operates efficiently and stably during the production process. At the same time, it provides all-round technical support to help customers solve various problems encountered in production.

Summary:

The PLA cup making machine, with its high efficiency, environmental protection and intelligent characteristics, meets the market demand for green and degradable packaging products, and is an important tool for the production of modern environmentally friendly products. Choosing a PLA cup making machine can not only effectively reduce production costs, but also help companies enhance their sense of social responsibility and respond to global environmental protection trends.