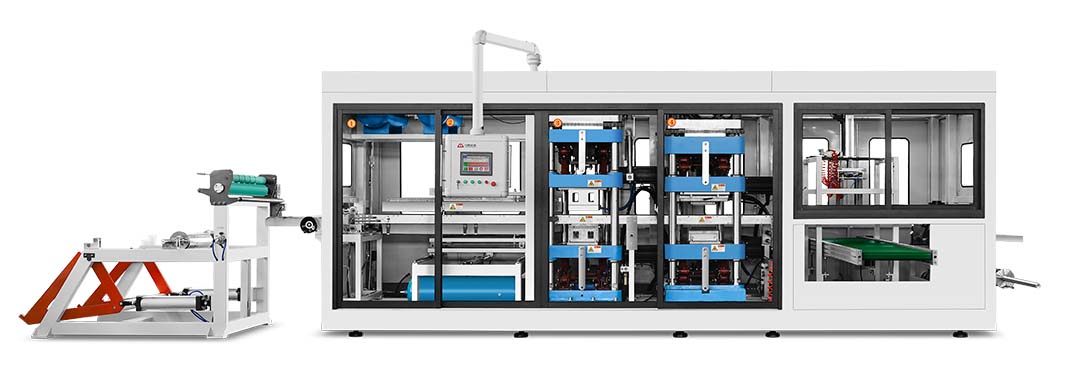

Plastic clamshell box thermoforming machine

Plastic clamshell box thermoforming machine is an advanced equipment specially used to produce various types of plastic clamshell boxes to meet the market's growing demand for packaging products. With its excellent performance and flexible adaptability, this machine has become an important tool in the plastic packaging industry.

Product Features

High efficiency: Using the latest thermoforming technology, the machine can complete heating and forming in a short time, significantly improving production efficiency and suitable for large-scale production.

Precision control: Equipped with an advanced PLC control system, it can accurately adjust the heating temperature and forming pressure to ensure that the size and shape of each flip box meet the standards.

Environmentally friendly materials: Supports the use of a variety of environmentally friendly plastic materials, such as PET, PP, PS, PVC, PLA, HIPS, etc., which helps companies achieve sustainable development goals.

Technical specifications

| MAIN TECHNICAL PARAMETER | |

| Model | TTF-520A |

| Forming Area | 520mm x 400 mm |

| Forming Depth (Max.) | 110mm |

| Sheet thickness | 0.2-1.6mm |

| Forming Speed (Max.) | 30times/min |

| Air pressure | 0.6-0.8mpa |

| Air consumption | 3.0 m³/min |

| Water consumption | 0.7 m³/h |

| Sheet width (Max.) | 550mm |

| Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA etc. |

| Power supply | AC 380V, 50Hz, Three-phase, Four-wire |

| Used power | 50Kw |

| Rated power | 120Kw |

| Heating power | 75Kw |

| Procedure | Forming-cutting-stacking |

| Dimension | L8200*W4650*H2670mm |

| Weight | About 9.0T |

Application scenarios

This thermoforming machine is widely used in multiple industries, including but not limited to:

Food packaging: suitable for making various food packaging, such as cake boxes, fruit and vegetable boxes, etc., to keep food fresh.

Daily products: can produce daily necessities packaging, such as washing product boxes, medicine packaging, etc.

Electronic products: Flip-top boxes that provide safety protection for electronic components and effectively prevent damage.

Advantages summary

Using a plastic flip-top box thermoforming machine can not only significantly reduce production costs, but also enhance the market competitiveness of products. Its high degree of automation reduces the need for manual operation, allowing companies to respond quickly to market changes. Choosing this equipment will enable companies to stand out in the fierce market competition.