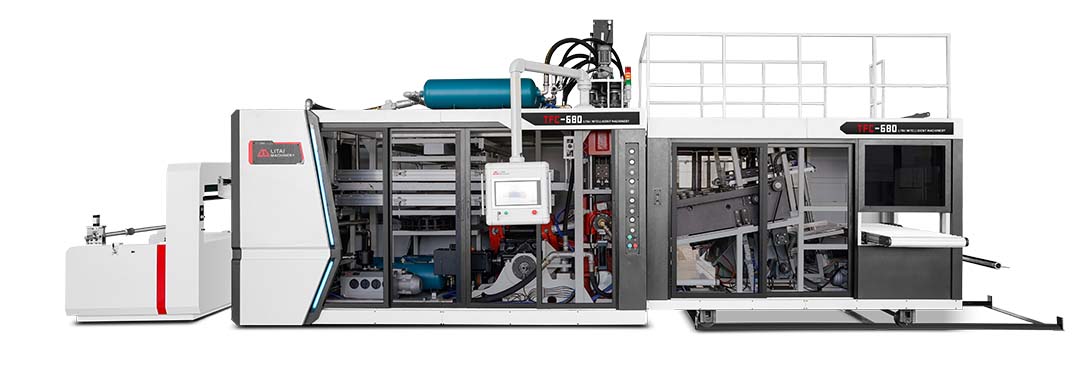

plastic cup thermoforming machine

Plastic cup thermoforming machine is a highly efficient equipment specially used for manufacturing various plastic cups, bowls, plates and other containers. The machine heats the plastic sheet, then forms it with a mold, and finally cuts out the finished product, achieving a quick conversion from sheet to final product. Plastic cup thermoforming machine is widely used in food packaging, beverage packaging, daily necessities and other fields, and is popular in the market for its high production efficiency and easy operation.

Product features:

Efficient production: The plastic cup thermoforming machine has a high degree of automation, and the whole process from sheet heating, forming to cutting is completed in one, which greatly improves production efficiency. The equipment supports continuous production and can meet the needs of mass production.

Precise control: The equipment is equipped with an advanced temperature control system and precise mold design, which can accurately control the heating temperature and molding pressure to ensure that the size of each product is consistent and the surface is smooth without additional trimming.

Versatility: The equipment supports the processing of a variety of materials, such as PP, PS, PET, PVC, PLA, HIPS, corn starch and other thermoplastic materials, and can produce plastic products of different specifications and shapes by replacing molds, and flexibly adapt to market demand.

Easy operation: The plastic cup thermoforming machine adopts PLC control system and human-machine interface, with a friendly operation interface. Workers only need simple training to get started, reducing dependence on technicians and reducing labor costs.

Energy saving and environmental protection: The equipment design takes energy consumption into consideration. By optimizing the heating system and insulation measures, it can effectively reduce energy consumption. At the same time, there is no exhaust gas emission during the production process, which meets environmental protection standards.

Safe and reliable: The machine is equipped with multiple safety protection measures, such as emergency stop button, overheat protection, etc., to ensure the safety and stability of the equipment during the production process.

Application scenarios:

Plastic cup thermoforming machines are widely used in the food industry, such as the production of disposable beverage cups, ice cream cups, yogurt cups, etc. In addition, it can also be used to make various daily plastic containers, such as salad bowls, etc., to meet the diverse needs of different consumer markets.

Summary:

The plastic cup thermoforming machine has become an ideal choice for the plastic product manufacturing industry with its advantages of high efficiency, flexibility and environmental protection. It can not only help enterprises improve production efficiency, but also reduce production costs and increase market competitiveness. For enterprises with large-scale plastic product production needs, the plastic cup thermoforming machine is undoubtedly an indispensable equipment.