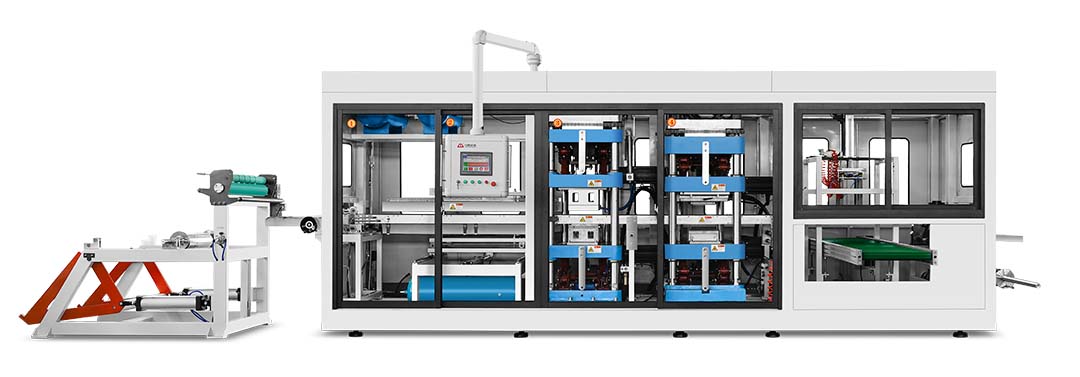

Plastic dinner cover thermoforming machine

The plastic tableware lid thermoforming machine is a highly efficient forming equipment designed for the food and beverage industry. It is mainly used to produce various disposable plastic tableware lids, cup lids and other packaging products. Compared with traditional production methods, this equipment not only improves product quality, but also greatly improves production efficiency. It is an important innovative equipment in the modern packaging industry. The following will introduce the equipment features, working principles, application scenarios and technical parameters in detail.

Product Features

Intelligent temperature control system

The temperature control system of the plastic dinner lid thermoforming machine adopts precise PID control, which can accurately adjust the temperature within 0.1℃. The heating system of the equipment uses ceramic infrared heating elements, which not only heats up quickly but also heats evenly. Before each molding, the system automatically adjusts the heating temperature to ensure that the plastic material softens at the optimal temperature, and ensures that the molded product has accurate dimensions and a smooth surface without defects.

High-speed production, improved efficiency

The equipment is equipped with a servo drive system, which can achieve high-speed and high-frequency molding. The servo drive makes the molding more accurate and the operation smoother, while also reducing the wear and maintenance frequency of the equipment. Generally, the production speed of the equipment is between 60 and 100 lids per minute, which greatly shortens the production cycle and is suitable for mass production tasks.

Modular design, flexible adaptation

The thermoforming machine adopts a modular design, and the mold and configuration can be flexibly replaced according to production needs. The equipment can support a variety of mold sizes and shapes, from small beverage lids to larger food dinner lids. The modular design concept also makes equipment maintenance more convenient, reduces downtime, and adapts to fast-paced production needs.

Energy saving and environmental protection, cost optimization

The energy-saving system of the equipment reduces energy consumption by 20%-30% through improved heating and cooling cycles. The heat recycling technology inside the system can effectively reduce heat loss, thereby achieving better molding effects while reducing energy consumption. At the same time, the equipment uses environmentally friendly materials and meets the green environmental certification standards of many countries, helping enterprises meet the requirements of sustainable development.

Humanized operation interface, convenient and efficient

The equipment is equipped with a high-definition touch screen, and the humanized operation interface provides clear production data and status display. Workers can set and adjust production parameters such as temperature, pressure, speed, etc. directly on the interface, and monitor production progress in real time. The system has an alarm function. When the equipment encounters an abnormal situation, the operation interface will automatically alarm and prompt solutions to ensure production safety and the service life of the equipment.

Working principle

The working principle of the plastic meal cover thermoforming machine is based on thermoforming technology. Simply put, the plastic material is formed by heating and pressure. The specific process is divided into the following steps:

Heating: Place the plastic sheet under the heating device. After uniform heating, the sheet softens at a suitable temperature and reaches a plastic state.

Molding: The softened plastic sheet is pressed into a pre-designed mold by air pressure or vacuum. The plastic material will cling to the mold surface and gradually form the desired shape.

Cooling and cutting: After molding, the system automatically performs cooling operations to ensure that the product size is stable and does not deform. Then the cutting system cuts the molded product into individual finished products to complete the production of the meal cover.

Applicable scenarios

Thermoforming machines for plastic meal covers are widely used in the food packaging industry, especially for companies that need to produce plastic beverage cup covers, fast food covers and food containers. The equipment is also very suitable for:

Fast food chain suppliers: For example, places that need to be equipped with integrated packaging covers for fast food such as hamburgers and fried chicken.

Beverage manufacturers: Suitable for the production of large quantities of disposable beverage cup covers such as coffee covers and milk tea covers.

Food processing plants: Food manufacturers with large demands for various plastic packaging, especially suitable for the production of packaging covers for fresh and frozen foods.

Technical Parameters

| MAIN TECHNICAL PARAMETER | |

| Model | TTF-520A |

| Forming Area | 520mm x 400 mm |

| Forming Depth (Max.) | 110mm |

| Sheet thickness | 0.2-1.6mm |

| Forming Speed (Max.) | 30times/min |

| Air pressure | 0.6-0.8mpa |

| Air consumption | 3.0 m³/min |

| Water consumption | 0.7 m³/h |

| Sheet width (Max.) | 550mm |

| Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA etc. |

| Power supply | AC 380V, 50Hz, Three-phase, Four-wire |

| Used power | 50Kw |

| Rated power | 120Kw |

| Heating power | 75Kw |

| Procedure | Forming-cutting-stacking |

| Dimension | L8200*W4650*H2670mm |

| Weight | About 9.0T |

The plastic dinner cover thermoforming machine has become an indispensable automated production tool for major food and beverage industries through its high-precision intelligent control and advanced energy-saving design. It not only improves production efficiency, but also ensures the high quality of products, bringing more stable production capacity guarantee and lower production costs to enterprises.