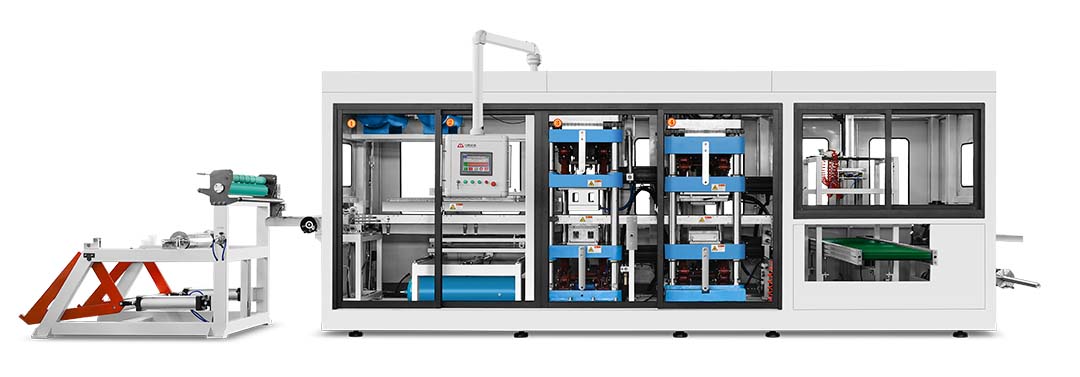

Plastic Egg Tray Thermoforming Machine

1. Product Overview

Thermoforming machine for plastic egg trays is a special equipment for manufacturing plastic egg trays using thermoforming technology. It is widely used in food packaging, agricultural product protection, retail industry, logistics and transportation. The equipment heats plastic sheets (such as PP, PET, PS, etc.) to a softened state, and then achieves precise shaping under the action of the mold, and then produces high-quality plastic egg trays through cutting and stacking processes. The equipment is designed with high efficiency, automation, energy saving and environmental protection as the core concept to meet the production needs of enterprises of different sizes.

II. Product Features

1. High-efficiency production capacity

The equipment adopts an integrated design of automatic feeding, molding, cutting and stacking, which is simple to operate and has extremely high production efficiency;

It can mold 20-30 times per minute, and the average daily production capacity of a single machine can reach tens of thousands of egg trays.

2. Precision molding technology

Equipped with high-precision molds to ensure the consistency of egg tray products in shape, size and strength;

The process of combining vacuum adsorption and pressure molding is adopted, and the finished product has no bubbles, no cracks, and the surface is smooth and flawless.

3. Intelligent control system

Equipped with advanced PLC control system, supporting touch screen operation interface, simple and intuitive operation;

Parameters such as heating temperature, molding pressure, feeding speed, etc. can be accurately adjusted to meet diversified production needs;

Real-time monitoring of equipment operation status, providing intelligent alarm and self-protection functions to ensure production safety.

4. Strong compatibility

Supports a variety of sheet materials, including PP, PS, PET, PVC, etc.;

Applicable to plastic sheets of different thicknesses (0.2-2.0mm), and flexible adjustment can meet customized needs.

5. Environmentally friendly and energy-saving design

Adopting an efficient and energy-saving heating system to reduce energy consumption and reduce the impact on the environment;

Supporting waste recycling and reuse functions, reducing raw material waste and reducing production costs;

The product meets food-grade environmental protection standards and can be used in the food industry.

III. Equipment workflow

1. Automatic feeding: The plastic sheet enters the heating zone through an automatic feeding device;

2. Heating and softening: The sheet is evenly heated in a multi-zone independent temperature-controlled heater to reach the softening temperature required for thermoforming;

3. Mold forming: The sheet is fed into the mold and precisely shaped through processes such as vacuum adsorption and pressure forming;

4. Cutting and trimming: The formed sheet is separated into independent egg trays by the cutting device;

5. Stacking output: The finished products after cutting are automatically stacked for subsequent packaging and transportation.

4. Technical Parameters

| MAIN TECHNICAL PARAMETER | |

| Model | TTF-520A |

| Forming Area | 520mm x 400 mm |

| Forming Depth (Max.) | 110mm |

| Sheet thickness | 0.2-1.6mm |

| Forming Speed (Max.) | 30times/min |

| Air pressure | 0.6-0.8mpa |

| Air consumption | 3.0 m³/min |

| Water consumption | 0.7 m³/h |

| Sheet width (Max.) | 550mm |

| Suitable Sheet | PP, PS, HIPS, PET, PVC, PLA etc. |

| Power supply | AC 380V, 50Hz, Three-phase, Four-wire |

| Used power | 50Kw |

| Rated power | 120Kw |

| Heating power | 75Kw |

| Procedure | Forming-cutting-stacking |

| Dimension | L8200*W4650*H2670mm |

| Weight | About 9.0T |

V. Application fields

1. Food packaging

Food protection packaging such as egg trays, egg boxes, fruit and vegetable trays;

2. Agriculture and logistics industry

Eggs and agricultural products transportation packaging, effectively preventing damage;

3. Retail industry

Supermarket egg packaging boxes, promotional blister trays;

4. Customized packaging

Plastic trays of other specifications or styles can be produced according to customer needs.

VI. Product advantages

Save labor costs: The equipment is fully automatic, easy to operate, and reduces the labor participation rate;

Shorten delivery cycle: high-efficiency production, fast completion of order requirements;

Improve product competitiveness: The finished product has a beautiful appearance and adapts to diverse market needs.

VII. After-sales service

1. Installation and commissioning service

Provide on-site installation and commissioning of equipment to ensure that customers can quickly put it into production;

2. Operation training

Professional team guides operation and maintenance to help customers master the use method;

3. Warranty support

Provide free technical support and spare parts replacement (non-human damage) within the one-year warranty period;

4. Long-term service

Provide low-cost repair services and technical support outside the warranty period.

Plastic egg tray thermoforming machine makes your packaging production more efficient and more environmentally friendly!