Plastic Sheet Machine

The plastic sheet machine is a high-efficiency equipment specializing in the production of plastic sheets. It is widely used in packaging, electronics, construction, automobile, medical and other industries. Its main function is to manufacture plastic sheets of different specifications from various types of plastic raw materials (such as PP, PS, PET, PVC, PLA, HIPS, etc.) through extrusion, calendering, cooling and other processes. Modern plastic sheet machines have the core characteristics of high efficiency, precision, environmental protection and automation, which can significantly improve production efficiency, reduce costs and ensure product quality.

Equipment structure and working principle

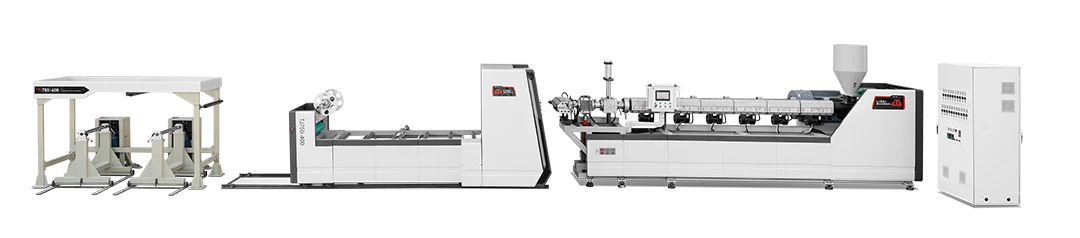

The working principle of the plastic sheet machine is to melt the plastic raw materials at high temperature, then extrude them through an extruder, and then make sheets of the required size and thickness through a series of subsequent process steps (such as calendering, cooling, cutting, etc.). The typical plastic sheet machine equipment structure includes the following parts:

1. Automatic feeding system: This system can automatically convey plastic granules or powdered raw materials to the main extruder to ensure the continuous supply of raw materials and reduce manual operation.

2. Extruder: This is the core part of the plastic sheet machine, mainly composed of a screw and a heating system. Through the rotation and shearing action of the screw, the plastic raw materials are melted, plasticized and pushed to the extrusion port. Extruders usually use single-screw, twin-screw or multi-screw designs according to different material properties to achieve the best mixing and extrusion effects.

3. Die head: The extruded molten plastic is extruded into a flat plate or thin sheet through the die head. The design of the die directly affects the width and thickness of the sheet, and can usually be adjusted according to production needs.

4. Calendering system: The extruded plastic is pressed by high-precision calendering rollers to form a sheet with a flat surface and uniform thickness. The calendering rollers are usually composed of multiple groups and equipped with a cooling system to ensure that the plastic is stably formed during the calendering process.

5. Cooling system: The sheet is quickly cooled by a cooling device (such as an air cooling or water cooling system) to shape the plastic sheet and obtain the final physical properties. The cooling process is very important, which is directly related to the surface smoothness, transparency and strength of the sheet.

6. Traction and cutting device: The cooled sheet is kept flat by the traction device, and then enters the cutting device to be cut into sheets of different widths or lengths as needed. The cutting device usually includes two methods: longitudinal cutting and cross-cutting, which can accurately control the size of the sheet.

7.Winding or stacking system: The cut sheet can be rolled into a roll by the winding system, or stacked into sheets by the stacking system for subsequent transportation and storage.

Main technical features

1. Efficient extrusion system: The optimized screw and precision heating system can evenly heat and fully plasticize different types of plastic materials, ensuring the stability and efficiency of the extrusion process and high production efficiency.

2. Multi-layer co-extrusion technology: Some high-end plastic sheet machines support multi-layer co-extrusion technology and can simultaneously produce multi-layer structure sheets, such as three-layer or five-layer co-extrusion. Such sheets usually have better mechanical properties and special functions, such as moisture resistance, impact resistance, barrier properties, etc.

3. High-precision thickness control: The plastic sheet machine is equipped with precision calendering rollers and online thickness measurement systems. By adjusting the calendering pressure and speed, the thickness of the sheet can be controlled in real time to achieve extremely high uniformity and precision.

4. Intelligent temperature control system: The heating zone in the equipment is equipped with a multi-stage independently controlled temperature control system, which can accurately adjust the temperature at different stages to ensure the temperature stability of the plastic in each link such as melting, extrusion, and calendering.

5. Automatic control system: Modern plastic sheet machines usually use PLC (programmable logic controller) and HMI (human-machine interface) control systems, integrating automatic tension control, speed synchronization, fault alarm and other functions, so that the entire production process can be fully automated, simple to operate and easy to maintain.

6. Energy-saving and environmentally friendly design: The equipment adopts an efficient and energy-saving electric heating system, and can be equipped with a waste recycling device to recycle the edge materials or waste generated during the production process, which meets the current requirements of environmentally friendly production.

Application areas

1. Packaging industry: Plastic sheets are widely used in the manufacture of various packaging materials, such as food trays, fast food boxes, pharmaceutical packaging, electronic product protective packaging, etc. PET, PP, PS and other sheets have become important materials in the packaging industry due to their high transparency, durability and moisture resistance.

2. Construction industry: Plastic sheets are widely used in the field of building materials, such as PVC sheets for waterproof rolls, thermal insulation materials and decorative panels, etc., with good anti-aging and anti-corrosion properties.

3. Electronics industry: In the manufacture of electronic products, plastic sheets are often used to make insulating boards, shielding materials and protective films, etc., especially in electrical housings and internal structural parts.

4. Automobile industry: Plastic sheets are used in the automotive field to make lightweight parts such as interior trims, dashboards, and door panels, which have the advantages of reducing weight, improving fuel efficiency and reducing costs.

5.Medical industry: Medical plastic sheets are usually used to make medical packaging, disposable medical devices, medicine trays, etc., and have high requirements for the hygiene and safety of the sheets.

Product Advantages

Efficient production: The plastic sheet machine has extremely high production efficiency and can complete mass production in a short time, which is suitable for large-scale industrial production needs.

Excellent product quality: The precision design and efficient control system of the equipment ensure the uniformity, smoothness and strength of the sheet, and the product quality is stable, which is suitable for high-demand application scenarios.

High degree of automation: The modern control system makes operation more convenient, reduces manual intervention, improves production efficiency, and reduces the error rate in the production process.

Environmental protection and sustainability: The plastic sheet machine supports the recycling and reuse of edge materials, which can effectively reduce material waste and production costs, while responding to environmental protection needs and reducing the impact on the environment.

Conclusion

As a highly automated and precise production equipment, the plastic sheet machine can provide high-quality plastic sheet products for various industries. With its flexible customization capabilities, high production efficiency and environmentally friendly design concept, the plastic sheet machine plays a vital role in modern industrial production. Choosing a high-quality plastic sheet machine can help enterprises improve production efficiency and expand market competitiveness.