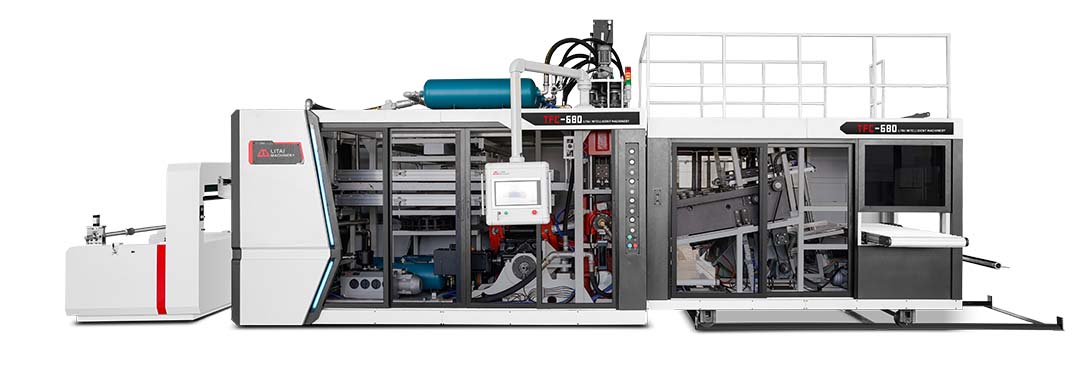

Plastic teacup thermoforming machine

Plastic teacup thermoforming machine is an efficient, intelligent and environmentally friendly production equipment designed for manufacturing disposable plastic teacups, beverage cups, food containers, etc. The equipment combines advanced thermoforming technology, precise mechanical technology and modern automatic control system to meet customers' needs for high-quality products and high production capacity.

1. Product Overview

The plastic tea cup thermoforming machine can quickly and efficiently process raw materials into plastic cups of various specifications by fully automating the heating, forming, punching and stacking of plastic sheets. The equipment is easy to operate and has stable performance. It is not only suitable for large-scale production in the food packaging industry, but also can flexibly meet diverse customization needs.

2. Main functional modules

1. Sheet conveying system

Automated sheet conveying device ensures that the sheet enters the heating zone stably.

Equipped with a tension adjustment system to avoid wrinkles or sliding of the sheet.

2. Heating system

Adopts multi-zone independent temperature control design to achieve precise heating adjustment.

The heating plate uses infrared or ceramic heating elements to evenly heat the surface of the sheet to avoid molding defects caused by uneven temperature.

3. Molding system

Use vacuum molding and air pressure assisted molding technology to ensure that the plastic cup has a full shape and clear details.

The molding mold can be quickly replaced to support the production of cups of various specifications.

4. Punching system

The high-speed punching device accurately cuts the molded product with smooth edges and no burrs.

The punching waste is automatically recycled to reduce resource waste.

5. Stacking and collection system

The molded products are neatly arranged by the automatic stacking device to facilitate subsequent packaging.

The intelligent stacking height is adjustable to meet different packaging needs.

6. Intelligent control system

Adopts PLC controller and touch screen human-machine interface, easy to operate, and real-time display of operating status.

Built-in fault alarm and safety protection mechanism to improve equipment reliability and operational safety.

3. Technical parameters

| MAIN TECHNICAL PARAMETER | |

| Machine Model | TFC-680 |

| Forming Area(L x W mm) | 680×320 |

| Forming Depth(Max.) | 170mm (180mm requires typesetting) |

| Sheet Width | 510-730mm |

| Suitable Sheet thickness | 0.3-2.0mm |

| Machine Forming Speed(Max.) | ≤42 times/min(depends on different products) |

| Air Pressure | 0.8-1.0Mpa |

| Air Consumption | 4000~5000 L/min |

| Water Consumption | 260 L/min |

| Water Pressure | ≥0.5Mpa (Can't turn on without enough pressure) |

| Suitable Sheet Materials | PP/PS/PET/PVC/PLA/Degradable material/etc |

| Power Supply | 380V 50HZ 3PHASE 4WIRE |

| Rated Power | 174KW |

| Heating rating | 129.6KW+ 2KW(preheating) |

| Punching Force | 32T |

| Procedure | Heating--Forming/Cutting--Stacking |

| Machine dimensions | L 10700mm* W 3088mm* H 3215mm |

| Machine Weight | 13.5T |

4. Product Advantages

1. Efficient production

The fully automated production line design allows for seamless delivery of raw materials and stacking of finished products, greatly reducing manual operations and improving production efficiency.

2. Precision molding

The mold processing has high precision, ensuring product size consistency and appearance aesthetics.

Supports complex cup design, such as products with patterns, LOGO or decorative edges.

3. Energy saving and environmental protection

The heating system is optimized to reduce energy consumption and reduce waste during production.

Supports the use of degradable and environmentally friendly materials, in line with the concept of green production.

4. Diverse adaptability

Can process a variety of materials (such as PP, PS, PET, etc.) to meet the diverse production needs of customers.

Supports one machine with multiple modes switching, flexible production of tea cups, beverage cups, food boxes and other products.

5. Smart and convenient

The friendly operation interface supports multi-language display, reducing the difficulty of worker training.

Intelligent fault diagnosis and alarm functions improve production continuity and maintenance efficiency.

V. Application fields

Food packaging industry: plastic tea cups, milk tea cups, ice cream cups, yogurt cups and other disposable food containers.

Beverage industry: various plastic cups used by beverage shops, milk tea shops, and cold drink brands.

VI. Equipment installation and after-sales service

1. Installation and commissioning

Provide on-site installation and commissioning services by professional engineers to ensure the normal operation of the equipment.

Free operation training to help customers quickly master the skills of using the equipment.

2. After-sales guarantee

Provide one-year equipment warranty and lifelong technical support services.

Adequate spare parts inventory to ensure fast replacement and repair.

3. Remote service

Support remote technical diagnosis and guidance to quickly solve problems in customer production.

VII. Summary

Plastic tea cup thermoforming machine is an important tool in the field of disposable plastic product manufacturing. Its high efficiency, intelligence and energy saving make it the preferred choice of many manufacturers. Whether it is small batch customization or large-scale production, the equipment can meet customer needs with excellent performance and create higher value for the enterprise.

Choose a plastic tea cup thermoforming machine to inject new impetus into your production! Welcome to contact us for more product information and solutions.