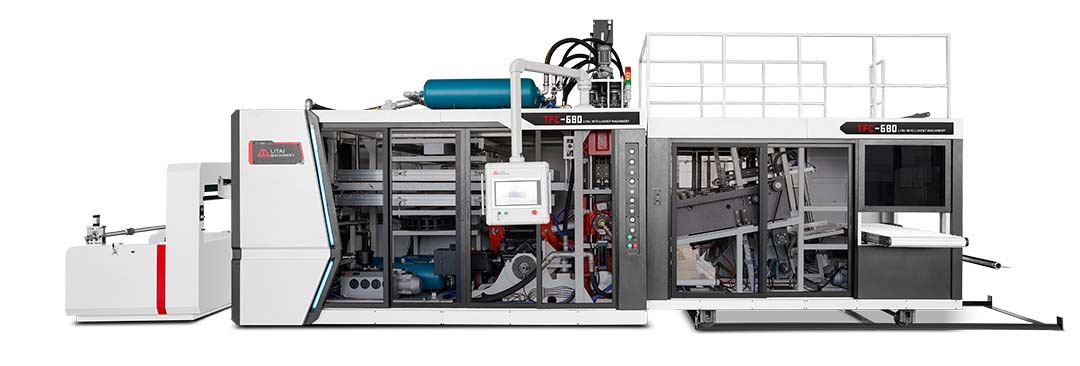

TFC-680 Flip Mold Thermoforming Cup Machine Product Introduction

TFC-680 Flip Mold Thermoforming Cup Machine Product Introduction

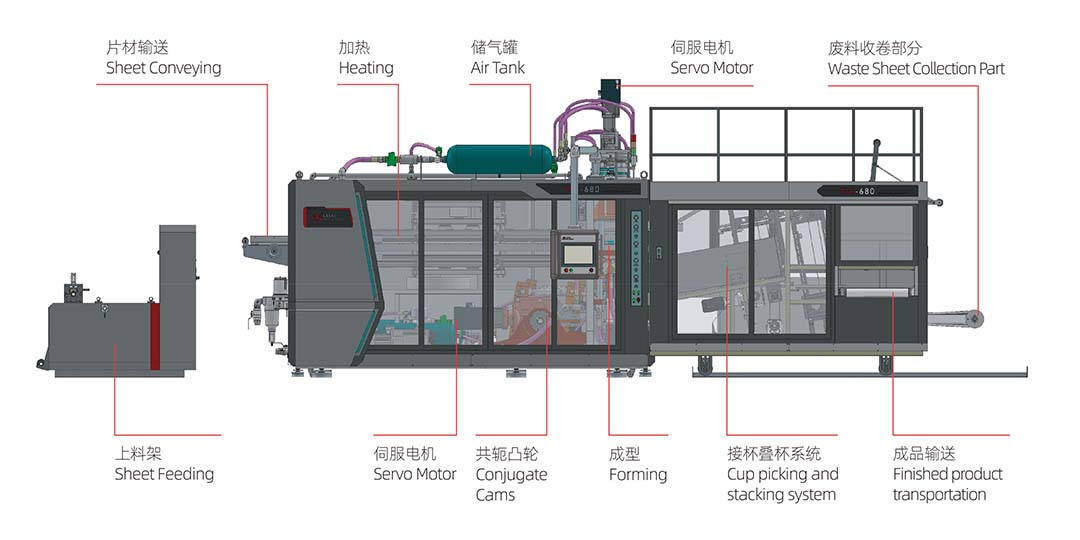

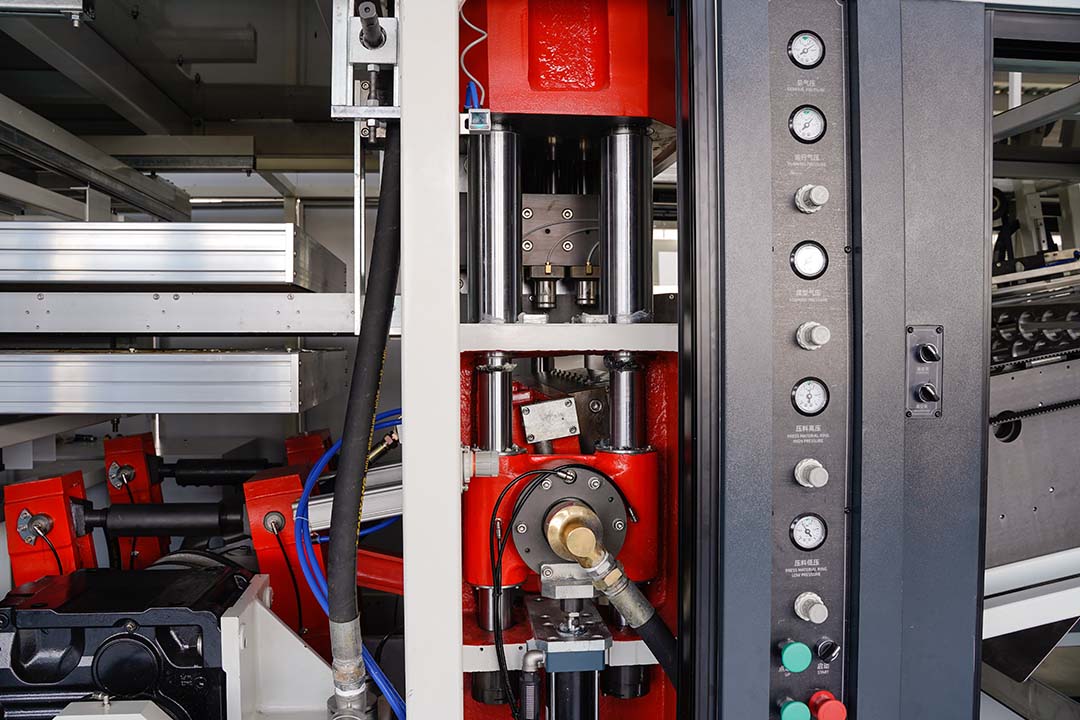

Plastic cup tilting thermoforming machine TFC-680 is the latest product developed by our company, mainly used to produce plastic cup products of different specifications. The machine adopts positive and negative pressure molding, equipped with a mold turning system under full servo motor control, and uses two pairs of conjugate cam transmission connecting rods to complete the tilting, lifting and punching of the mold table. It is a new type of equipment developed for high output, low energy consumption, high stability, high automation and other requirements, providing a perfect solution for medium and high capacity disposable plastic cups.

Product Features

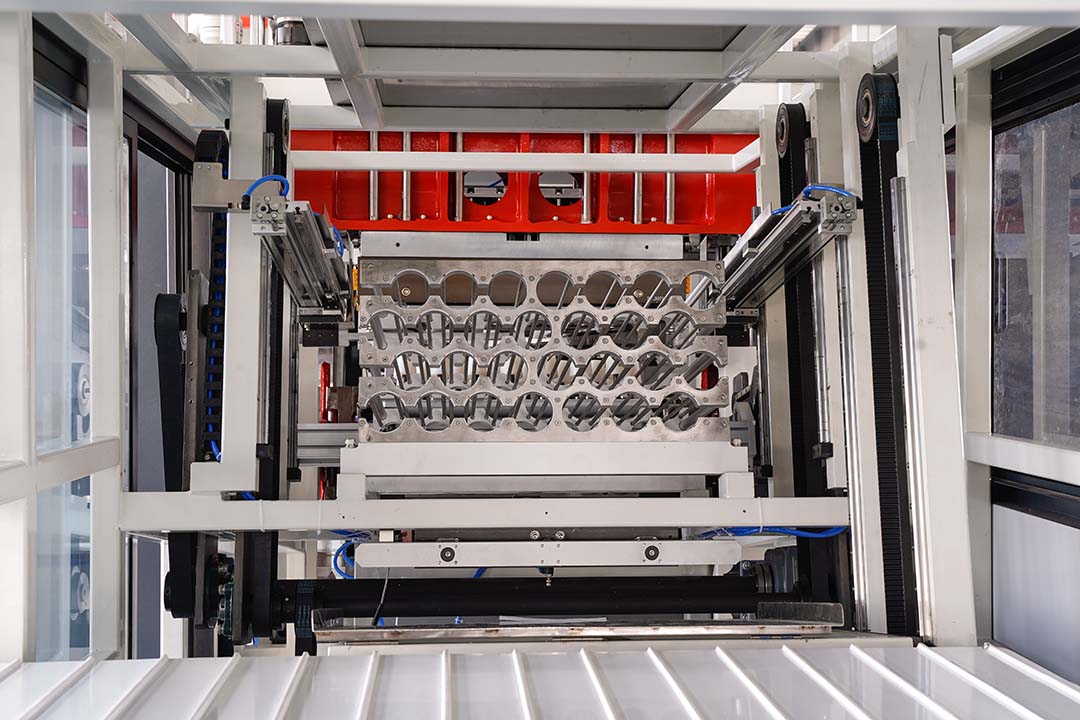

Efficient production: The flip mold thermoforming cup machine has high-speed production capacity and can produce tens of thousands of cups per hour, which greatly improves production efficiency and is suitable for large-scale production. The cup receiving is driven by a servo motor, and the independently developed V-shaped flip device can achieve rapid cup suction, flipping, and stacking, which is suitable for products of various calibers and cup heights. The cup sweeping and pushing are controlled by a servo motor. When the count is in place, the product can be quickly swept onto the conveyor belt according to the number of rows of formed products.

Versatility: The equipment supports the processing of a variety of materials, including PP, PS, PET, PVC, PLA, etc., and can produce cups of different materials. At the same time, the mold table can be flexibly adjusted to suit the production of various cup types.

High precision: Through advanced thermoforming technology and precise mold tilting device, the size and shape of each cup are ensured to be consistent, reducing the scrap rate and improving product quality. The feeding adopts servo motor driven sprocket transmission, with high feeding accuracy and fast start and stop response; the chain track opens and closes semi-automatically; and the tension of the chain track can be easily adjusted.

High degree of automation: Equipped with a fully automatic control system, it can realize the automation of the entire process from sheet feeding, heating and forming, mold flipping to finished product output, reducing the complexity of manual operation and reducing production costs. The entire system adopts B&R central controller (Chinese and English programs) and human-machine interface control, which has a high degree of integration, accurate control, and easy operation. Automatic loading and feeding saves human resources, reduces the load of the conveying servo motor, and can be operated by one person, which is efficient and convenient.

Environmental protection and energy saving: The thermoforming cup machine adopts energy-saving design, reduces energy consumption, supports the use of degradable materials, and meets environmental protection requirements. The heating area (electric furnace) is 2250mm long and uses German ceramic heating tiles. The upper heating zone has 36 zones and the lower heating zone has 12 zones, a total of 48 zones (see attached picture). The temperature control module is used for the entire temperature control. The solid-state relay has no contact output, which is stable and accurate. The temperature control error is ≤±1℃.

Application Fields

TFC-680 flip mold thermoforming cup machine is widely used in food packaging industry, especially in the production of beverage cups, yogurt cups, pudding cups, etc.

Technical Parameters

| MAIN TECHNICAL PARAMETER | |

| Machine Model | TFC-680 |

| Forming Area(L x W mm) | 680×320 |

| Forming Depth(Max.) | 170mm (180mm requires typesetting) |

| Sheet Width | 510-730mm |

| Suitable Sheet thickness | 0.3-2.0mm |

| Machine Forming Speed(Max.) | ≤42 times/min(depends on different products) |

| Air Pressure | 0.8-1.0Mpa |

| Air Consumption | 4000~5000 L/min |

| Water Consumption | 260 L/min |

| Water Pressure | ≥0.5Mpa (Can't turn on without enough pressure) |

| Suitable Sheet Materials | PP/PS/PET/PVC/PLA/Degradable material/etc |

| Power Supply | 380V 50HZ 3PHASE 4WIRE |

| Rated Power | 174KW |

| Heating rating | 129.6KW+ 2KW(preheating) |

| Punching Force | 32T |

| Procedure | Heating--Forming/Cutting--Stacking |

| Machine dimensions | L 10700mm* W 3088mm* H 3215mm |

| Machine Weight | 13.5T |

After-sales service

We provide comprehensive after-sales service, including equipment installation, commissioning, training and maintenance, to ensure that customers can smoothly put into production and operate stably in the long term. Our technical team is always ready to provide support to customers and solve any problems encountered during the production process.

Thermoforming cup machine TFC-680 has become the ideal choice for many companies with its high efficiency, precision and versatility. If you have any needs or questions, please feel free to contact our sales team, we will serve you wholeheartedly.