TQC-750 Plastic Cup Thermoforming Machine Product Introduction

1. Overview

TQC-750 plastic cup thermoforming machine is a highly efficient mechanical equipment designed for the production of various plastic cups. It uses thermoforming technology to produce various types of plastic cups by heating plastic sheets (such as PP, PET, PS, etc.) and forming them in the mold under hydraulic drive. The automatic feeder adopts square steel structure, which is highly wear-resistant, more stable and efficient. The whole machine adopts PID temperature control system, with high display accuracy and temperature control tolerance <1℃. This equipment is widely used in the food and beverage industry and is an indispensable production equipment on the market.

2. Main features

Efficient production

High-speed operation: For example, 30,000 plastic cups can be produced per hour for a cup with an upper diameter of 90mm, which can meet the needs of large-scale production and greatly improve the production efficiency of the enterprise.

High degree of automation: Equipped with automatic feeding, forming, cutting, stacking and counting functions, it realizes fully automatic production, reduces manual intervention and reduces labor costs.

Precise Control

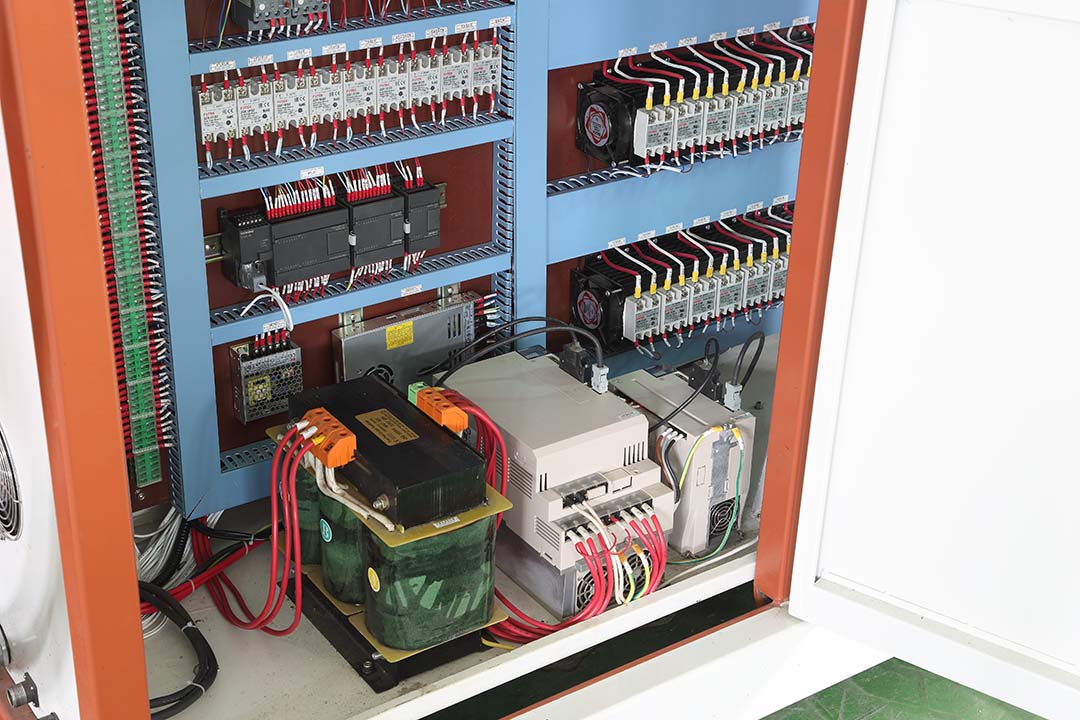

Temperature Control System: Using advanced PLC programmable controller, it can accurately adjust and monitor the heating temperature to ensure uniform heating of plastic sheets, thus ensuring stable quality of finished products.

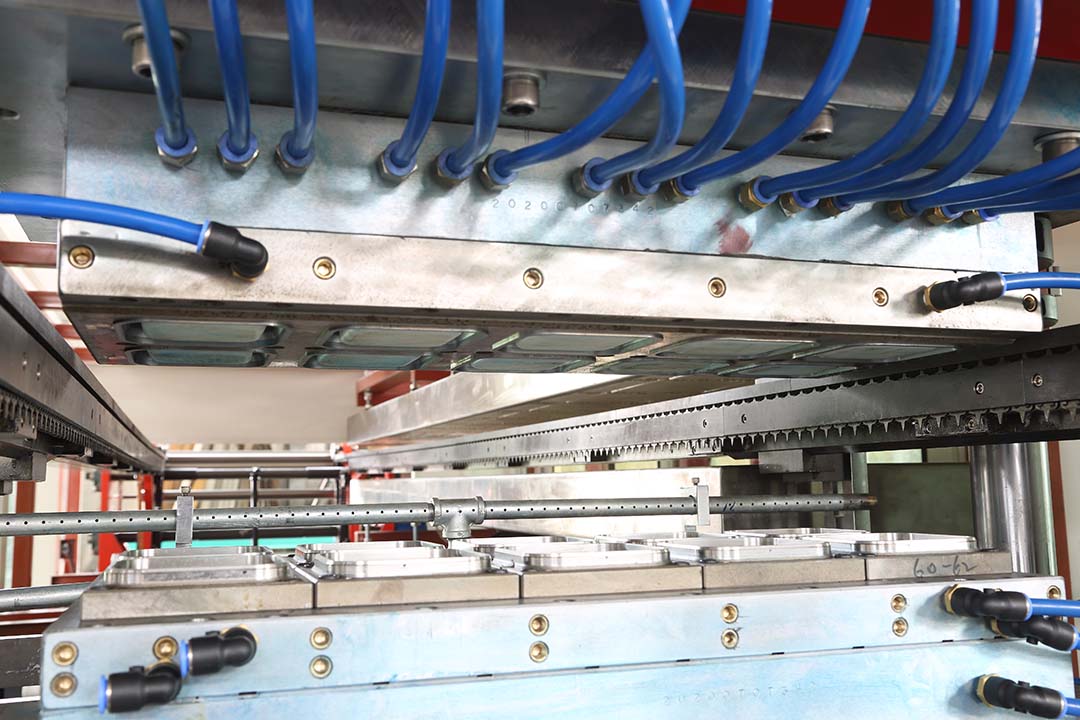

Molding pressure control: Through the precise pressure adjustment system, it ensures that each plastic cup can be molded under appropriate pressure to reduce the defective rate.

Strong flexibility

Easy mold replacement: The equipment design takes into account the diverse production needs, and molds of different specifications and shapes can be quickly replaced to adapt to market changes.

Wide range of applicable materials: The equipment is compatible with a variety of thermoplastic materials, such as PP, PET, PS, etc., to meet the needs of different customers.

Easy to operate

Friendly human-machine interface: The device is equipped with an intuitive touch screen control panel, which is easy to learn and operate, and provides multi-language interface options for easy use by users around the world.

Intelligent monitoring system: monitors the equipment operation status in real time, provides fault diagnosis and alarm functions, and ensures stable equipment operation.

Energy saving and environmental protection

High-efficiency energy-saving design: The equipment adopts an efficient heating system to reduce energy consumption and production costs.

Environmentally friendly exhaust system: Equipped with an advanced exhaust system, it effectively reduces harmful gas emissions and meets environmental protection requirements.

- Technical parameters

| TECHNICAL PARAMETER | |

| Model | TQC-750 |

| Max. Forming Area | 750*480mm |

| Max. Forming Depth | 125-180mm |

| Sheet Thickness | 0.3-1.8mm |

| Sheet Width | 760mm |

| Max. Forming Speed | 30 times/min |

| Air Pressure | 0.6-0.8mpa |

| Air Consumption | 3.0m³/min |

| Water Consumption | 0.7m³/h |

| Rated Power | 173Kw |

| Used Power | 98Kw |

| Power Supply | AC 380V,50Hz, Three-phase, Four-wire |

| Dimension | L8500*W2200*H3200mm |

| Weight | About 6.5T |

4. Application fields

Disposable plastic cup thermoforming machines are widely used in the catering food and beverage packaging industry, including but not limited to:

Cold drink cups: ice cream cups, milkshake cups, cold drink cups, etc.

Hot drink cups: coffee cups, tea cups, etc.

Others: yogurt cups, juice cups, bowls, boxes, etc.

5. Reasons for purchase

High productivity: meet mass production needs, shorten delivery cycle, and improve market competitiveness.

Quality Assurance: Precisely controlled production processes ensure stable quality of finished products and compliance with international food safety standards.

Versatility: One machine has multiple uses and can flexibly produce plastic cups of different specifications and shapes to adapt to the diverse needs of the market.

Cost control: High-efficiency and energy-saving design significantly reduces production costs and improves corporate profitability.

6. After-sales service

We provide comprehensive after-sales service, including:

Equipment installation and commissioning: Professional team will install and commission on site to ensure the normal operation of the equipment.

Operation training: Provide detailed operation training for customers to help them quickly master the use of equipment.

Regular maintenance: Provide regular maintenance services to ensure the long-term stable operation of the equipment.

Technical support: 24/7 technical support, quickly respond to customer needs and solve equipment problems.

7. Summary

TQC-750 plastic cup thermoforming machine is the core equipment in the production of modern plastic products. With its high efficiency, flexibility, energy saving and easy operation, it has become the ideal choice for many companies. Choosing our equipment can not only improve production efficiency and product quality, but also effectively reduce production costs and enhance market competitiveness.

For more product details or quotation information, please feel free to contact our sales team. We look forward to working with you to create a better future together.